It is important to inspect a wire rope sling so that you can avoid injuries and damages. Inspections need to be done on a daily basis, and reviews need to done in a specific order. Going through these steps is the best way to safeguard employees and property. By implementing a three level inspection strategy, you can make sure all slings are evaluated at the proper intervals.

Before going over the specifics of wire rope sling inspection, it is important to note that one designated individual should be allowed to conduct thorough inspections: a qualified and well-trained professional. Trusting anyone else is a mistake.

Before going over the specifics of wire rope sling inspection, it is important to note that one designated individual should be allowed to conduct thorough inspections: a qualified and well-trained professional. Trusting anyone else is a mistake.

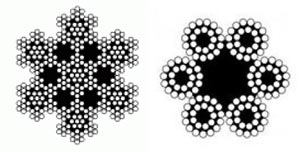

The most important test a trained professional will conduct is a spot check. This means that they will give a visual inspection of the whole sling. All parts of the sling must be inspected (this means hard to see areas). It is important to clean your sling prior inspection so that dirt and dust do not make a visual inspection more difficult.

Prior to use, all new, used, altered, modified or repaired slings shall be inspected.

A wire rope sling shall be removed from service if any of the following conditions are present:

- Missing or illegible Sling identification/capacityTags

- Broken Wires

- Extensive Scraping and Abrasions

- Kinking, crushing, birdcaging or any other damage to the rope structure

- Fittings that are cracked, deformed or worn

- Evidence of heat damage

- Severe corrosion to the rope or the fittings

If any of the above are encountered, a sling must be promptly removed from service and destroyed. Even if there is only minimal damage, a sling should be taken out of service and destroyed. Never underestimate the importance of inspecting and maintaining perfectly working wire rope slings.

Related Reading