Regarding rigging equipment and lifting loads, there are different materials to choose from. One of the most common concerns to pop up is deciding between the use of synthetic, chain, or wire rope slings. They have their pros and cons, and each material has specific rules and safety standards.

Regarding rigging equipment and lifting loads, there are different materials to choose from. One of the most common concerns to pop up is deciding between the use of synthetic, chain, or wire rope slings. They have their pros and cons, and each material has specific rules and safety standards.

Deciding between chain, synthetic, or wire rope slings depends on the rigger's preference and equipment. Some loads will warrant a specific type of sling. We can help you choose the right material for your needs. Before making your decision, you must understand the characteristics of each material.

Synthetic Slings

These slings are made of synthetic fibers, usually nylon. Nylon slings are not as durable as metal slings but do not require lubrication and have an excellent strength-to-weight ratio. These slings are not recommended when handling loads in high temperatures as they can burn or melt.

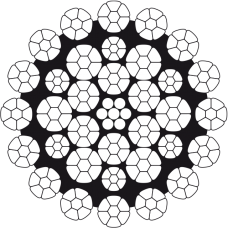

Wire Rope Slings

Wire rope slings are highly durable and feature high working load limits. While wire rope slings require lubrication, this should not be an issue. The manufacturer will recommend which lube to use and the steps to take for proper lubrication. Because these slings are not as flexible as synthetic slings, they are not ideal for use when going around a tight corner.

Chain Slings

Like wire rope, chain slings are highly durable and have exceptional working load limits. They are heavier in larger sizes. All team members must follow the manufacturer's recommendations for proper care and safety.

Related Reading about Wire Rope