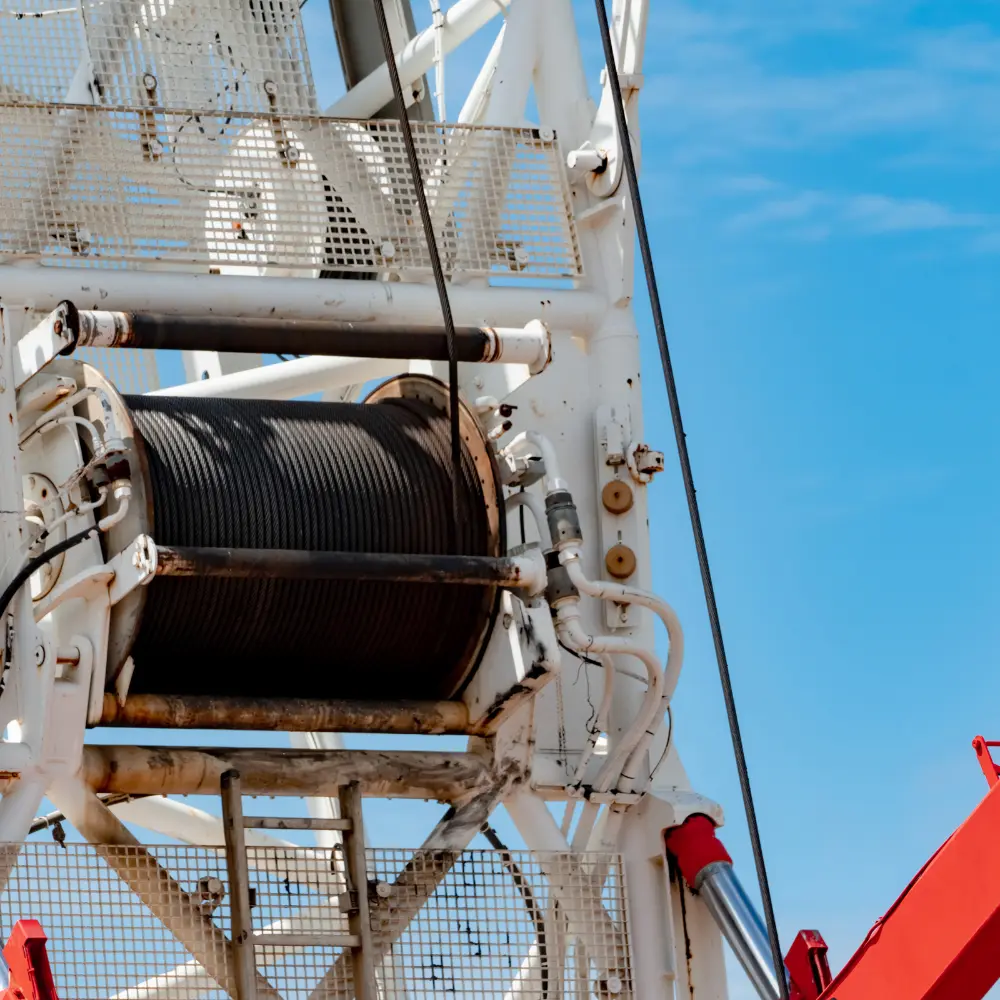

In the complex domain of crane operations, the nuanced interplay between wire rope and pulley systems is foundational to the machinery's performance and longevity, particularly when subjected to varying loads. This interaction significantly dictates the efficiency of crane operations and the lifespan of wire ropes. Insights into the tribological behavior between wire ropes and pulleys highlight the necessity of optimizing this interaction to bolster performance and durability.

In the complex domain of crane operations, the nuanced interplay between wire rope and pulley systems is foundational to the machinery's performance and longevity, particularly when subjected to varying loads. This interaction significantly dictates the efficiency of crane operations and the lifespan of wire ropes. Insights into the tribological behavior between wire ropes and pulleys highlight the necessity of optimizing this interaction to bolster performance and durability.

Tribological Behavior and Surface Wear Analysis

Explorations into the frictional interactions between wire rope and pulleys have illuminated the impact of contact loads on the wire rope's friction coefficient (COF), surface temperature, and wear patterns. Notably, the COF exhibits a decreasing trend with an increase in sliding distance, reaching a minimal value under specific load conditions. This underscores the critical influence of contact load on the tribological dynamics between the wire rope and the pulley.

Further, the surface temperature of wire ropes shows a rapid increase at the outset, stabilizing within a specific range across varying loads. Examination of wear scars reveals an irregular pattern, with wear width expanding in response to increased contact loads. These observations are pivotal for devising strategies to mitigate wear and enhance the operational lifespan of wire ropes in crane systems.

The Influence of Contact Load on Surface Wear and Bending Fatigue Life

Increased contact loads are found to smooth the wear surfaces on wire ropes, primarily through abrasive and adhesive wear mechanisms. Surface wear is a significant determinant in reducing wire ropes' bending fatigue life. This degradation in anti-bending fatigue properties is more pronounced under larger sliding contact loads, emphasizing the necessity of precision in operational conditions to maintain the integrity and functionality of wire ropes.

Strategies for Extending Wire Rope Lifespan

To optimize the performance of crane wire ropes and pulleys under various loads, proper lubrication must be ensured, wire ropes with properties tailored to specific operational needs must be selected, and optimal contact loads must be maintained. These strategies improve the operational efficiency of crane machinery and are vital for upholding safety standards.

Getting the Best Wire Rope

The interaction between wire ropes and pulleys under different loads is critical to crane operation, directly affecting performance and lifespan. Elucidating the effects of contact loads on friction, surface wear, and bending fatigue life has provided valuable insights for optimizing crane operations. Implementing strategic measures to understand and reduce wear can significantly extend the operational life of wire ropes, ensuring efficiency and safety in crane operations.

Related Reading