Wire ropes are indispensable in numerous industrial and mechanical applications, from construction to shipping. Their strength, flexibility, and reliability make them a cornerstone in heavy lifting and load-bearing tasks. Yet, the efficacy and safety of these vital tools hinge significantly on their correct handling, storage, and maintenance. From the initial stages of uncoiling and unreeling to the complexities of drum winding and the nuances of proper storage, each step in the lifecycle of a wire rope is pivotal.

Wire ropes are indispensable in numerous industrial and mechanical applications, from construction to shipping. Their strength, flexibility, and reliability make them a cornerstone in heavy lifting and load-bearing tasks. Yet, the efficacy and safety of these vital tools hinge significantly on their correct handling, storage, and maintenance. From the initial stages of uncoiling and unreeling to the complexities of drum winding and the nuances of proper storage, each step in the lifecycle of a wire rope is pivotal.

The care and attention given to these processes extend the ropes' functional lifespan and ensure the safety of the operations they facilitate. Understanding the technicalities and best practices in handling wire ropes is thus not just a matter of efficiency but of utmost importance for operational safety and effectiveness.

Guidelines for Uncoiling and Unreeling Wire Ropes – Maximizing Safety and Efficiency

Uncoiling and unreeling wire ropes correctly prevent damage that can compromise their integrity and functionality. This section provides detailed guidelines on handling these processes effectively, emphasizing the importance of technique and caution to maintain the safety and longevity of the ropes.

- Understanding the Importance of Safe Uncoiling: The process of uncoiling wire ropes demands specific techniques to prevent the formation of kinks and loops, which can lead to permanent damage. Below are the best practices and common pitfalls to avoid during uncoiling.

- Techniques to Handle Wire Rope Coils

- Lay the free end of the coil on the floor and stand the coil on the edge. Unroll it carefully to maintain the rope's structure.

- Alternatively, place the coil on a revolving shaft to uncoil, ensuring even and controlled unwinding.

- Common Mistakes to Avoid

- Never lay a coil on its side and pull the rope out, as this can create twists and kinks that weaken the rope.

- Key Guidelines for Proper Unreeling of Wire Ropes: Unreeling wire ropes also requires a careful approach to avoid creating loops or twists that could lead to structural weaknesses. Here are the essential steps and cautionary measures for unreeling wire ropes.

- Handling Techniques for Wire Rope Reels

- Support the reel on a pipe or bar through the center hole, allowing the reel to revolve freely as the rope is pulled off.

- Use a timber brake against the reel flange to provide back tension for uniform unwinding.

- Strategies to Prevent Damage During Unreeling

- Avoid laying the reel on its side and pulling the rope over the flange, as this can cause severe distortion and kinks.

Following these guidelines for uncoiling and unreeling wire ropes will ensure the ropes remain in optimal condition, ready for safe and efficient use in various applications. Proper handling in these initial stages is critical in the overall maintenance and care of wire ropes.

Prevention of Kinking and Rope Damage – Essential Handling Techniques

Proper handling of wire ropes to prevent kinking and other damage is crucial for maintaining their integrity and functionality. This section explores the causes of such damage and provides guidelines on handling wire ropes to avoid these issues, thus ensuring their longevity and safe usage.

- Identifying Causes of Kinks in Wire Ropes: Kinks in wire ropes are often a result of improper handling, particularly during uncoiling and unreeling processes. Understanding these causes is the first step in prevention.

- Kinks usually begin with the formation of a loop. If a rope is mishandled, especially if it's laid on its side and the rope is pulled out, it can lead to the development of loops, which eventually tighten into kinks.

- Improper practices in uncoiling and unreeling can produce a spiral condition in the rope that is challenging to remove and often leads to kinking, compromising the rope's strength.

- Steps to Avoid Kinking: It is crucial to follow specific procedures to prevent kinking, which can irreparably damage the wire ropes.

- Always use the correct uncoiling and unreeling methods. This includes standing coils on edge and using revolving shafts for controlled unwinding.

- Handle the wire rope carefully throughout its installation, avoiding any practices that might cause loops or twists.

- Handling Techniques to Maintain Rope Integrity: Maintaining the structural integrity of wire ropes involves more than just correct uncoiling and unreeling; it extends to every aspect of their handling.

- If a loop forms in the rope, it can be removed by rotating the rope at either end in the right direction to restore the lay, provided the loop hasn't been pulled tight.

- In cases where a kink has been tightened, that section of the rope has suffered permanent damage and should not be used. Regular inspections for kinks and distortions are essential.

Understanding the causes of kinks and following these guidelines for proper handling can significantly reduce the risk of damaging wire ropes. This prevention of kinking and other forms of damage ensures the safety and efficiency of wire rope applications.

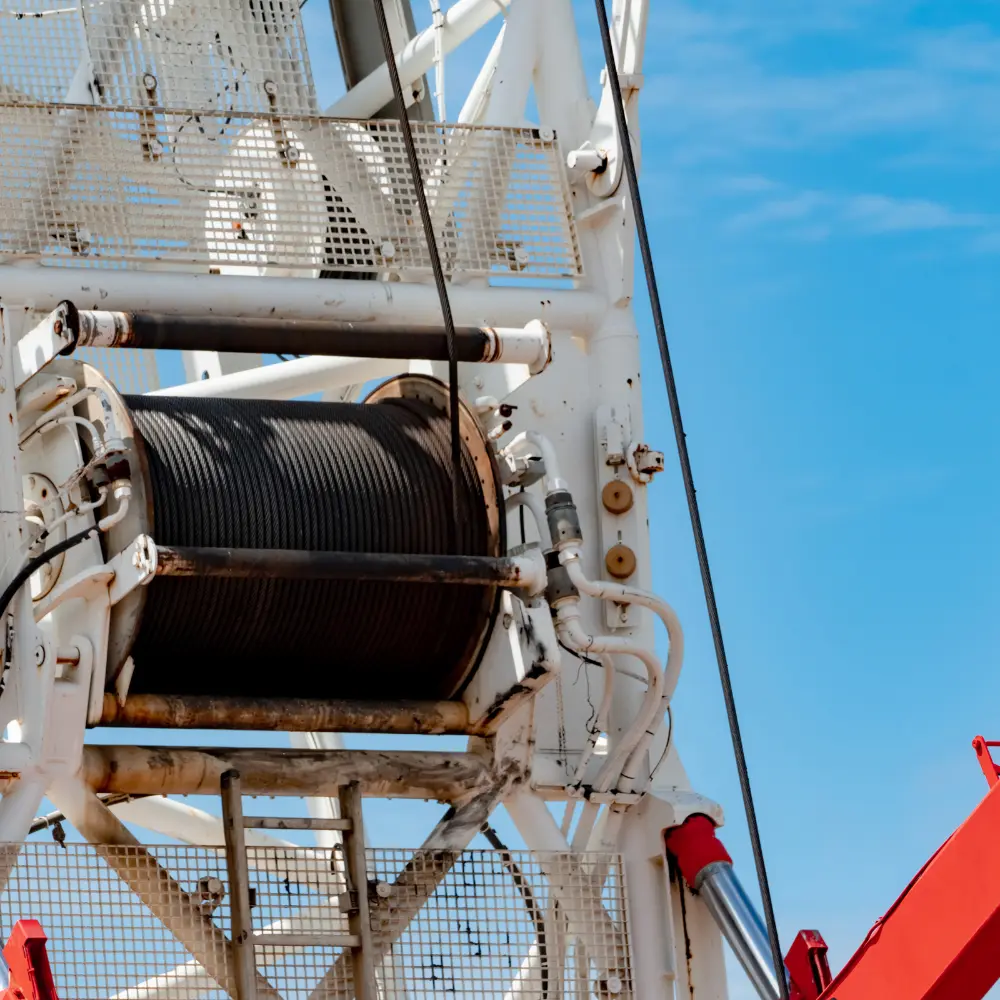

Drum Winding Techniques – Optimizing Wire Rope Performance

Effective drum winding techniques are essential for maximizing the performance and lifespan of wire ropes. This part of the guide delves into the intricacies of drum winding, highlighting the importance of understanding the rope's rotational tendencies and the different types of winch drums used in the process.

- Understanding the Rotational Tendency of Wire Ropes: How wire ropes are wound on drums determines their overall performance and longevity. A key aspect to consider is the rope's natural tendency to rotate.

- Wire ropes are constructed with a spiral lay of strands, which imparts a slight rotational tendency when spooled onto a drum.

- Recognizing whether a wire rope is right-lay or left-lay is crucial in determining how it should be wound to effectively utilize its natural rotational direction.

- Types of Winch Drums and Their Usage: Different winch drums require specific winding techniques to ensure optimal performance of the wire ropes.

- Grooved Drums - Grooved drums provide a guided path for the wire rope, making it easier to wind it neatly and uniformly. They are generally effective for both right-lay and left-lay ropes due to the control offered by the grooves.

- Smooth-faced Drums - When using smooth-faced drums, the rope's rotational tendency becomes more influential in achieving tight and uniform winding. The fleet angle, or the angle at which the rope approaches the drum, plays a significant role in how the rope winds on these drums.

- Correct Attachment Points for Wire Ropes: Proper attachment of the wire rope to the drum is crucial for safe and efficient winding.

- For right-lay ropes on an overwind drum, attach the rope's end to the left flange of the drum. Conversely, for underwind reeving, attach it to the right flange.

- For left-lay ropes, the attachment points are opposite to those for right-lay ropes. This ensures the rope's natural rotation aids the winding process, preventing piling or uneven winding.

Understanding and implementing the right drum winding techniques are paramount in preserving the quality and functionality of wire ropes. By considering the rope's rotational tendencies and selecting the appropriate type of drum and attachment points, one can significantly enhance its performance and extend its service life.

Proper Storage of Wire Ropes – Ensuring Durability and Safety

Proper storage of wire ropes is a critical aspect of their maintenance, directly impacting their longevity and performance. Understanding the ideal conditions and practices for storing wire ropes can significantly extend their service life, ensuring durability and safety.

- Recommended Storage Conditions for Wire Ropes

- Ensuring Protection from Weather Elements - Wire ropes, an essential component in various industrial applications, demand careful storage to maintain their integrity. The primary rule for storing wire ropes is to keep them in a place shielded from weather elements. Exposure to moisture, sunlight, or extreme temperatures can accelerate the deterioration process of the ropes. Moisture, in particular, is a notorious culprit for causing rust and corrosion in metal, leading to weakened wire ropes that are prone to failure. Therefore, a dry, temperate, and ideally indoor environment is optimal for storing wire ropes.

- The Necessity of Acid-Free Environments - Another critical factor in storing wire ropes is ensuring an acid-free environment. Even the slightest trace of acid or acid fumes can cause significant damage to wire ropes. This damage often goes unnoticed until the rope is used, leading to catastrophic failures. Acidic environments can rapidly degrade the metal, compromising the rope's strength and integrity. Thus, storing wire ropes away from any chemicals, particularly acids, or areas where they might have been stored previously is crucial.

- The Critical Nature of Preventing Acid Damage: Acid damage to wire ropes is not always immediately apparent but can lead to serious safety hazards. When wire ropes come into contact with acids, even in small amounts, the acid can seep into the crevices and corrode the wires from within. This internal damage weakens the rope's overall structure, making it prone to snapping under load. It's essential to regularly inspect stored wire ropes for any signs of acid damage, such as discoloration or brittleness, and to replace any rope that shows these symptoms.

- Effective Lubrication Strategies for Stored Wire Ropes: An often-overlooked aspect of wire rope storage is the role of lubrication. Applying a lubricant layer to the wire ropes protects them from corrosion and helps maintain their flexibility and strength. The lubricant acts as a barrier against moisture and other corrosive elements. Use a high-quality lubricant designed for wire ropes to ensure the best protection. This lubricant should coat the outside layer of the wire rope, especially when stored on a reel or coil. Regularly checking and reapplying lubricant as necessary is integral to wire rope maintenance.

The storage of wire ropes is a fundamental practice that requires attention to detail and understanding the environmental factors that can affect their condition. The integrity and reliability of wire ropes can be significantly preserved by ensuring protection from weather elements, avoiding acidic environments, and applying proper lubrication. These practices extend the life of the ropes and ensure the safety of the operations in which they are used. Remember, the care taken in storing wire ropes today can prevent failures and accidents tomorrow.

Related Reading