Taking care of rigging supplies is essential for the safety of employees and businesses. Problems with rigging supplies can create a bad name for a company, and so safety should be a high priority when operating. Training employees in understanding wire rope degradation can help them to spot issues more clearly and to address them appropriately. Below, we will go over a small diagnostic guide designed to understand typical wire rope degradations better.

Tension: This break will reveal a mixture of cone/cup fractures and shear breaks. The problem is usually caused by overloads, sticky clutches, loosened drum bearings, wrong wire rope size, or more. You want to check for the strain on the rope after degradation has weakened it.

Abrasion: This break shows mainly on outer wires that are worn smooth like a knife edge. Wire broke by abrasion, when combined with other factors, will show combination breaks. Check for change in load, overburdened changes, or change in rope or sheave size. Other factors could be the excessive fleet angle, misalignment of sheaves, and improperly attached fittings.

Mashing: This break shows spread and flattened wires at both ends. When this problem occurs, check for mechanical abuse (abnormal or accidental forces).

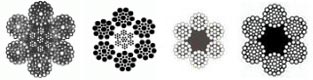

Wire Rope

For more information on caring for stainless steel wire rope, reach out for rigging supplies New York.

Related Reading: