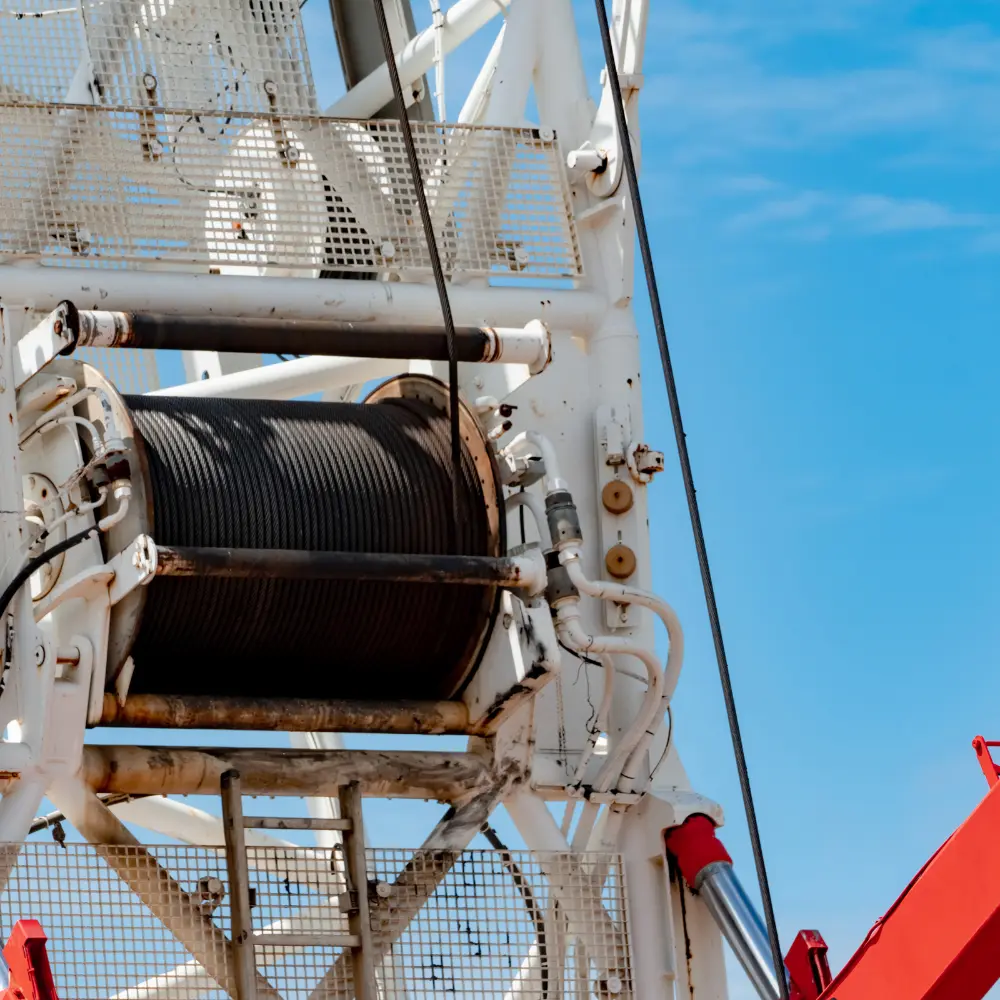

The failure of steel wire ropes poses a significant risk in various industrial applications. These ropes, known for their strength and flexibility, are crucial in construction, maritime, and civil engineering. Despite their robust design, wire ropes can still succumb to damage and failure due to a complex interplay of factors. However, by examining these factors and implementing preventive measures, we can enhance their operational reliability, reassuring us of our proactive approach. The premature failure of steel wire ropes primarily results from mechanical stresses, environmental conditions, and cumulative damage that compromise their structural integrity.

The failure of steel wire ropes poses a significant risk in various industrial applications. These ropes, known for their strength and flexibility, are crucial in construction, maritime, and civil engineering. Despite their robust design, wire ropes can still succumb to damage and failure due to a complex interplay of factors. However, by examining these factors and implementing preventive measures, we can enhance their operational reliability, reassuring us of our proactive approach. The premature failure of steel wire ropes primarily results from mechanical stresses, environmental conditions, and cumulative damage that compromise their structural integrity.

How Do Mechanical Stresses Initiate Wire Rope Degradation?

Wire ropes are engineered to endure heavy loads and resist tension, but mechanical stresses can gradually weaken their internal structure. Overloading, for example, places excess strain on the ropes, pushing them beyond their designed capacity. This stress causes internal wires to bend and stretch, leading to localized fatigue that escalates with continued use. Notably, improper installation practices, such as incorrect tensioning, add to these mechanical stresses, setting the ropes toward early degradation.

Moreover, once mechanical stresses set in, they trigger a domino effect of damage. Repeated bending and shock loading further exacerbate the wear on the wire's internal strands. Wire ropes exhibit a progressive decline in their ultimate static force during tensile testing as strand failures increase. This ongoing weakening highlights the need for strict adherence to load specifications and installation protocols to mitigate the onset of mechanical damage.

Environmental Exposures Accelerate Failure

While mechanical stresses mark the beginning of degradation, environmental conditions often intensify this process. Wire ropes are frequently exposed to moisture, chemicals, and extreme temperatures that accelerate corrosion. This exposure is especially problematic for ropes used in marine environments, where saltwater corrosion rapidly diminishes the protective coatings on the wires, leading to brittleness and breakage under tension.

In addition to corrosion, environmental abrasion contributes to ropes' decline. Wire ropes utilized in abrasive environments, such as construction or mining, endure constant contact with rough surfaces. This contact wears down the outer strands, leaving the internal structure vulnerable to further damage. The combination of external wear and environmental exposure hastens the rope’s failure, underscoring the importance of regular inspection and timely maintenance.

What Is the Role of Cumulative Damage in the Failure Process?

As environmental and mechanical factors degrade wire ropes, cumulative damage becomes a central factor in their eventual failure. Cumulative damage results from the slow accumulation of defects over time, gradually diminishing the rope's strength. Static damage plays a crucial role here, directly impacting the rope's ability to bear loads. During this process, the residual ultimate force—the measure of the rope's remaining strength—declines as the number of broken strands increases.

This decline is not linear; static damage evolves through distinct stages. Initially, the damage increases slowly, causing minimal impact on the rope's overall performance. However, as the degradation progresses, the damage accelerates, reaching a critical fraction of life where failure becomes imminent. This dynamic illustrates the need for static damage modeling, a predictive approach that helps determine the rope's lifespan and identify when preventive maintenance is necessary.

How Does Fatigue Weaken the Wire Rope Over Time?

Fatigue further compounds cumulative damage, weakening wire ropes through repeated stress cycles. Unlike other structural elements, wire ropes have numerous intertwined wires that can tolerate minor damage without immediate failure. However, with ongoing use, these repeated stress cycles lead to fatigue, reducing the rope's endurance limit—the maximum stress it can endure without breaking.

As fatigue progresses, the rope's load-bearing capacity diminishes, resulting in a brittle fracture of the compromised strands. This gradual weakening necessitates frequent monitoring and maintenance to catch early signs of fatigue. By identifying fatigue-induced damage early, operators can reinforce or replace the ropes before a catastrophic failure occurs.

Knowledge Helps Prevent Wire Rope Failure

Wire rope failure results from a convergence of mechanical stresses, environmental factors, and cumulative damage. Each element contributes to a gradual decline in the rope's structural integrity. By taking an integrated approach to maintenance—combining stress management, environmental control, and static damage monitoring—it's possible to significantly reduce the risk of sudden failures and enhance the reliability of wire rope systems in demanding applications.

Related Reading