In harsh industrial environments, where equipment is subjected to continuous cyclic loads, the performance of wire ropes becomes critical. One of the most significant challenges in these environments is fretting—a wear mechanism that occurs at the contact points between two surfaces under repeated loading. Fretting can lead to premature failure of wire ropes, especially when the materials chosen are not optimized for the specific conditions.

In harsh industrial environments, where equipment is subjected to continuous cyclic loads, the performance of wire ropes becomes critical. One of the most significant challenges in these environments is fretting—a wear mechanism that occurs at the contact points between two surfaces under repeated loading. Fretting can lead to premature failure of wire ropes, especially when the materials chosen are not optimized for the specific conditions.

The impact of material selection on fretting behavior cannot be overstated. From the composition of the wire itself to the types of coatings applied, every decision plays a crucial role in determining the rope’s resistance to fretting fatigue. This article explores how different materials, such as carbon steel, galvanization, and synthetic cores, influence the durability of wire ropes in extreme conditions.

The choice of material is a critical determinant in wire rope performance, dictating its resistance to fretting wear and fatigue in harsh environments.

What Is Fretting, and Why Does It Matter?

Micro-movements at the contact points result in fretting wear when two surfaces rub against each other under repeated motion. In wire ropes, this often happens between individual wires or at the interfaces where the rope interacts with pulleys or other mechanical components. Over time, these micro-abrasions can evolve into cracks, weakening the rope's overall structure and increasing the risk of failure.

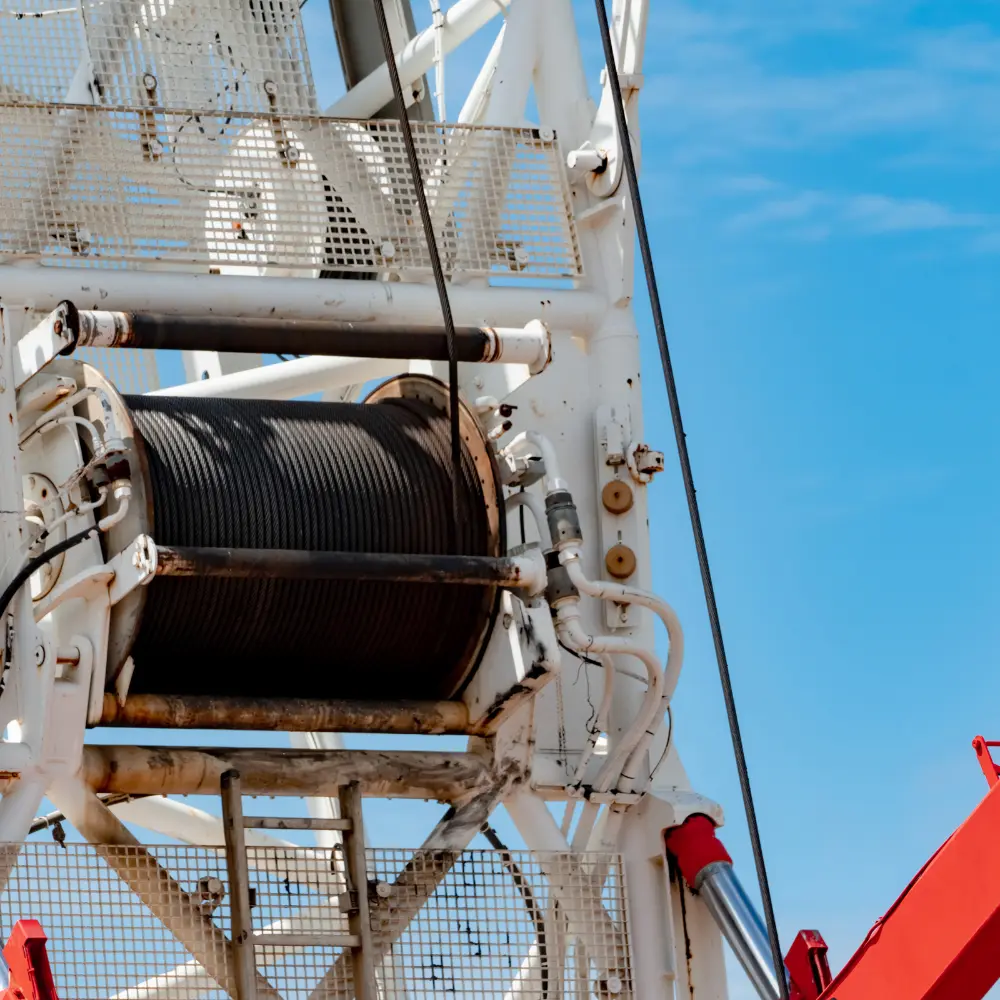

Wire rope used in shipping, construction, and mining industries is frequently exposed to heavy loads, cyclic tension, and environmental stressors such as corrosion and moisture. These conditions make choosing materials that can withstand fretting over long periods imperative.

How Does Material Composition Affect Fretting Behavior?

The base material used in wire ropes is fundamental in how well it withstands fretting. Wire ropes are typically made from carbon steel, which offers high tensile strength, but the level of carbon content can influence the rope’s resistance to wear and fatigue. For example:

- Carbon Steel: High-carbon steel wire ropes are more fatigue-resistant due to their increased hardness. However, this can make them more brittle, requiring careful consideration of the environment and load conditions. Carbon steel ropes are often cold drawn, which enhances tensile strength and reduces flexibility, which can impact fretting resistance.

- Galvanized Coatings: Galvanized steel wire ropes, such as your 6X19 CLASS GALV IWRC IMPORT, benefit from a zinc coating that protects against corrosion and fretting wear. This is particularly advantageous in marine and outdoor applications, where moisture accelerates fretting.

How Does Core Selection Influence Fretting?

The core of a wire rope can be either metallic or synthetic, and this choice significantly impacts how the rope behaves under fretting stress. Fiber-core ropes, such as your 6X19 CLASS BRT FIBER CORE, offer more flexibility than wire-core alternatives, which makes them more resistant to fretting fatigue in specific applications. However, they may lack the tensile strength of steel cores, making them more suitable for lighter loads.

On the other hand, independent wire rope cores (IWRC), found in products like the 6X19 CLASS GALV IWRC DOMESTIC, provide superior strength and durability but may require more frequent lubrication to protect against fretting. The IWRC’s metallic structure gives it greater load-bearing capacity, which is beneficial in applications where strength is paramount.

Environmental Considerations: How Harsh Conditions Exacerbate Fretting

Fretting behavior becomes even more pronounced when moisture, salt, and temperature extremes occur. For instance, in coastal or offshore settings, the combination of saltwater exposure and cyclic loading accelerates corrosion and fretting wear. This is where material selection is critical; products like galvanized wire ropes, such as your 6X19 CLASS GALV IWRC IMPORT, excel in these conditions due to their protective zinc coating, providing security in harsh environments.

Moreover, the base material’s resistance to thermal stress becomes equally crucial in high-temperature environments, such as foundries or manufacturing plants. Wire ropes that feature heat-resistant coatings or are made from materials with high heat tolerance are more likely to withstand fretting damage over time.

Choose the Right Material to Mitigate Fretting of Wire Ropes in Harsh Environments

As professionals in the shipping, construction, and mining industries, your role in material selection is crucial in minimizing fretting behavior in wire ropes. Each aspect of the rope’s construction, from the base metal to the type of core and protective coatings, influences its ability to resist wear and fatigue in harsh conditions. Whether for marine, industrial, or construction applications, ensuring the right combination of materials is crucial for extending the lifespan and performance of wire ropes.

Bilco Group, with its extensive knowledge and experience, offers a range of high-quality wire ropes designed to withstand the rigors of harsh environments. Understanding the fretting behavior of different materials and selecting the suitable rope for your needs can ensure safety, durability, and efficiency in even the most demanding applications.

Related Reading