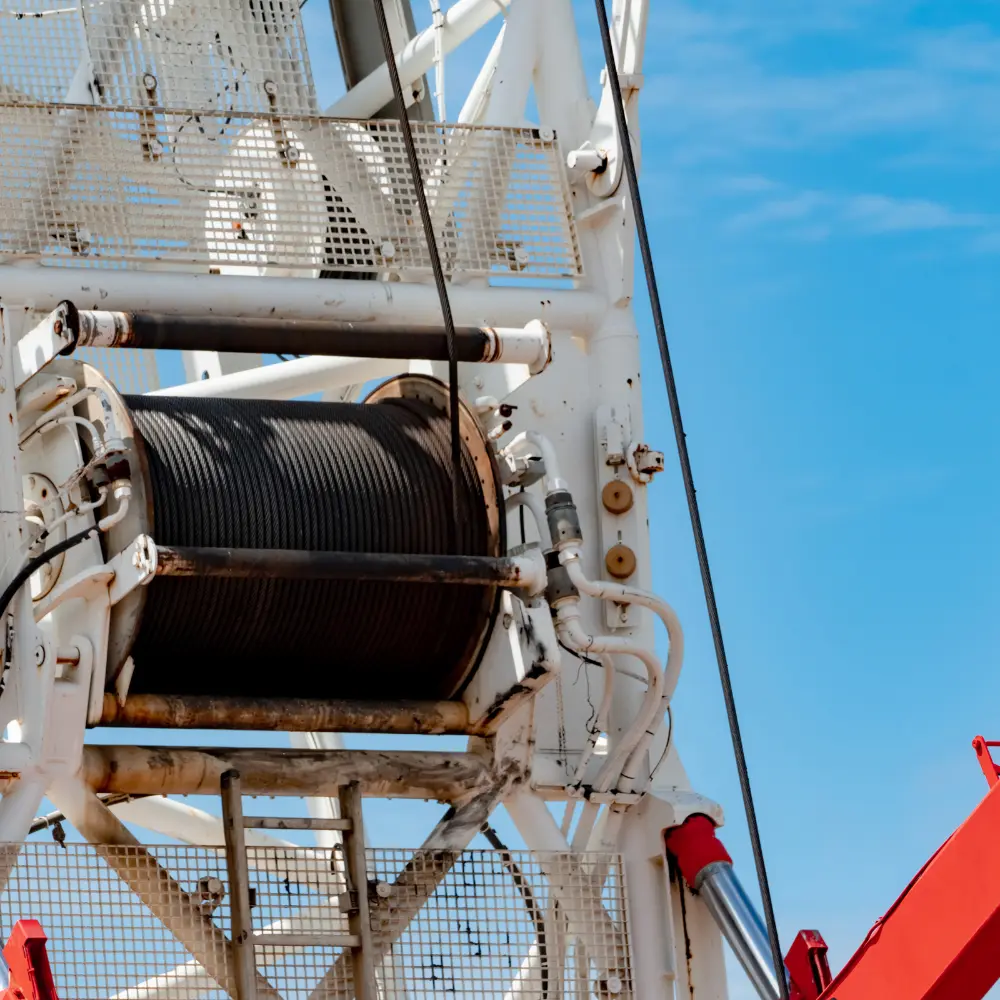

Steel wire ropes, crucial for handling immense loads under harsh conditions, require the utmost integrity for safety and operational efficiency. Traditional methods often miss internal damage, making Non-Destructive Testing (NDT) indispensable. By evaluating steel wire ropes without causing damage, NDT methods play a pivotal role in detecting flaws that could lead to premature failure. The application of specific NDT techniques to steel wire ropes provides the essential data professionals need to bolster safety and reliability.

Steel wire ropes, crucial for handling immense loads under harsh conditions, require the utmost integrity for safety and operational efficiency. Traditional methods often miss internal damage, making Non-Destructive Testing (NDT) indispensable. By evaluating steel wire ropes without causing damage, NDT methods play a pivotal role in detecting flaws that could lead to premature failure. The application of specific NDT techniques to steel wire ropes provides the essential data professionals need to bolster safety and reliability.

How NDT Applies to Steel Wire Ropes

Non-destructive testing (NDT) is a suite of techniques used to assess the condition and integrity of materials without damaging them. NDT focuses on identifying internal damage, such as wire breaks, corrosion, and fatigue, for steel wire ropes that may not be visible during a visual inspection.

Essential NDT Methods for Steel Wire Ropes

- Magnetic Flux Leakage (MFL): This method detects surface and internal defects by magnetizing the steel wire rope. When the rope passes through a magnetic field, defects such as broken wires or corrosion create a leakage in the magnetic field, which sensors can detect. MFL is particularly effective for identifying internal wire breaks and severe wear.

- Electromagnetic Testing (ET): ET uses electromagnetic fields to detect variations in the rope's structure, making it ideal for spotting material degradation due to fatigue or corrosion. This method identifies changes in the rope's physical properties that are invisible during surface inspections.

- Ultrasonic Testing (UT): Ultrasonic waves are transmitted through the rope, and any disruption in the wave's travel caused by internal defects is recorded. UT effectively detects internal flaws like cracks or voids, especially in complex, multi-strand wire ropes.

These methods provide comprehensive inspections without dismantling the wire ropes, saving time and preventing unnecessary downtime.

Real-World Data on NDT Effectiveness

NDT has proven its effectiveness in preventing premature failures across industries. In the offshore oil and gas sector, regular NDT inspections reduced rope failure rates by over 35%, particularly in dynamic environments where visual inspections alone would miss critical damage. Construction companies that implemented NDT reported fewer incidents of rope breakage and extended the lifespan of their equipment by up to 25%.

For example, magnetic flux leakage (MFL) has a 90% accuracy rate in detecting internal wire breaks, making it a preferred method for high-stress applications. While more complex, ultrasonic testing (UT) has an 85% success rate in identifying internal corrosion and fatigue cracks, especially in multi-strand wire ropes where traditional inspections often fall short.

Advantages of NDT Over Visual Inspections

Visual inspections are limited to detecting surface-level damage. However, many failures in steel wire ropes occur internally, making NDT essential for comprehensive detection. Key advantages include:

- Internal Damage Detection: NDT identifies internal wire breaks, corrosion, or wear that are invisible to standard visual inspections. A rope that looks fine externally may have internal wire breaks, which NDT methods like MFL can detect early.

- Reduced Risk of Catastrophic Failures: By detecting internal defects before they worsen, NDT significantly reduces the risk of sudden rope failures, which can result in costly downtime or even fatal accidents. This relief from potential catastrophic failures instills a sense of security and confidence in the reliability of the equipment.

- Minimized Equipment Downtime: NDT allows for ongoing monitoring without halting operations or dismantling equipment, saving time and money in industries such as shipping, mining, and construction. This efficiency in minimizing equipment downtime reassures the audience about the continuity of operations.

Safety Through Testing Wire Ropes

Non-destructive testing (NDT) has proven invaluable in preventing premature failures in steel wire ropes. By detecting internal damage early, NDT significantly enhances the safety and reliability of hoisting systems. The safety benefits of NDT make the audience feel secure and protected, knowing that potential risks are being actively managed.

Related Reading