When operating in harsh marine environments, the right rope choice is not just a matter of preference but a responsibility that can mean the difference between seamless performance and operational failures. Marine applications demand ropes that withstand constant water, salt, and tension exposure. This is where chafe gear, synthetic ropes, and rigging supplies come into play. Choosing the right combination ensures marine operations' safety, efficiency, and extended service life. Proper rope selection is necessary for optimal performance and safety in marine settings.

When operating in harsh marine environments, the right rope choice is not just a matter of preference but a responsibility that can mean the difference between seamless performance and operational failures. Marine applications demand ropes that withstand constant water, salt, and tension exposure. This is where chafe gear, synthetic ropes, and rigging supplies come into play. Choosing the right combination ensures marine operations' safety, efficiency, and extended service life. Proper rope selection is necessary for optimal performance and safety in marine settings.

Why is Rope Selection Critical in Marine Environments?

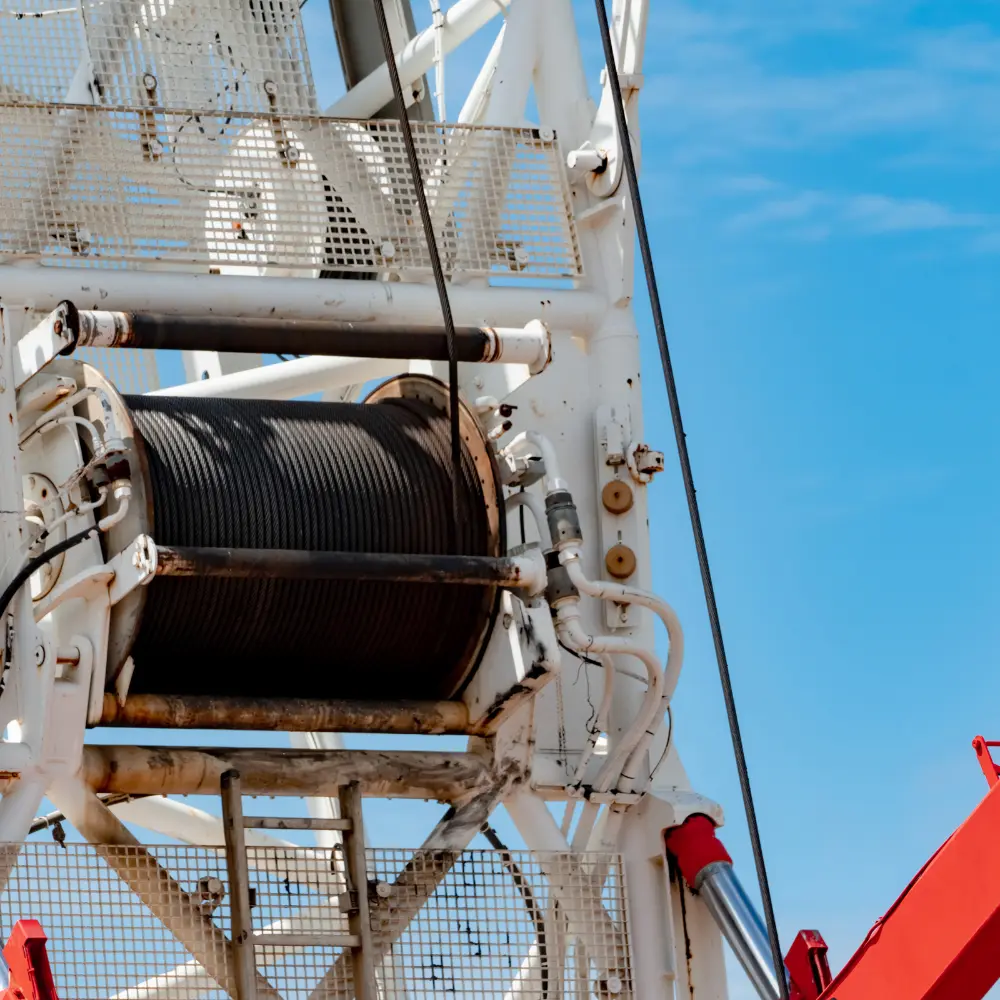

Marine environments present unique challenges, such as constant exposure to moisture, saltwater corrosion, and high-tension applications. Synthetic lifting ropes have become increasingly popular due to their superior strength-to-weight ratio and resistance to corrosion. However, not all synthetic ropes are created equal. The choice of rope material, construction, and coating directly impacts its performance in marine settings, making careful selection vital.

What Role Does Chafe Gear Play in Rope Longevity?

Chafe gear is not just an accessory but a crucial component in marine rope maintenance. It acts as a protective layer, shielding synthetic hoist lines from abrasion caused by contact with surfaces like boat decks, docks, and other marine equipment. For instance, synthetic ropes used in mooring lines often experience wear due to constant friction. Using chafe gear is a proactive measure that preserves the rope’s integrity, significantly extending its service life. Without chafe gear, ropes are vulnerable to premature wear, which can compromise safety and efficiency.

How Do Rigging Supplies Impact Rope Performance?

Appropriate rigging supplies are not just additional tools but crucial for maintaining the structural integrity of synthetic hoist lines. Improper rigging can lead to excessive tension, twisting, and even rope failure. For example, mismatched hooks, shackles, or pulleys can cause uneven load distribution, increasing the risk of fatigue and abrasion. Choosing the right rigging supplies is a proactive step that enhances the rope's performance and contributes to safer marine operations by ensuring it remains within its designed load limits.

What Factors Should Guide Your Synthetic Lifting Rope Selection?

Selecting the correct synthetic hoist lines involves considering several factors:

- Tensile Strength: The rope's capacity to withstand tension is critical in high-stress marine applications.

- Abrasion Resistance: A rope with high abrasion resistance is essential, especially in environments where it will contact rough surfaces.

- Weight: Lightweight ropes reduce the load on the vessel and enhance maneuverability.

- Flexibility: A flexible rope is easier to handle and can adapt to various rigging configurations. Rigorously evaluating these factors ensures that the rope selected meets the specific demands of the marine environment.

If Safety is Essential, Correct Rope Choice is Critical:

Ask the Wire Rope Experts

Proper rope selection is crucial in marine applications. Using chafe gear, appropriate synthetic lifting ropes, and high-quality rigging supplies ensures safety, operational efficiency, and cost-effectiveness. By focusing on these aspects, marine professionals can make informed decisions that lead to longer-lasting ropes and safer marine activities.

Related Reading