The effectiveness of hoisting ropes in preventing corrosion is crucial in various industrial applications. Corrosion can significantly impact the lifespan and reliability of these ropes, leading to potential safety hazards and increased maintenance costs. This article focuses on the corrosion resistance of diverse types of hoisting ropes, specifically steel wire ropes and synthetic ropes. The discussion will cover material composition, protective measures, environmental factors, and maintenance practices influencing their corrosion resistance.

The effectiveness of hoisting ropes in preventing corrosion is crucial in various industrial applications. Corrosion can significantly impact the lifespan and reliability of these ropes, leading to potential safety hazards and increased maintenance costs. This article focuses on the corrosion resistance of diverse types of hoisting ropes, specifically steel wire ropes and synthetic ropes. The discussion will cover material composition, protective measures, environmental factors, and maintenance practices influencing their corrosion resistance.

Steel Wire Ropes

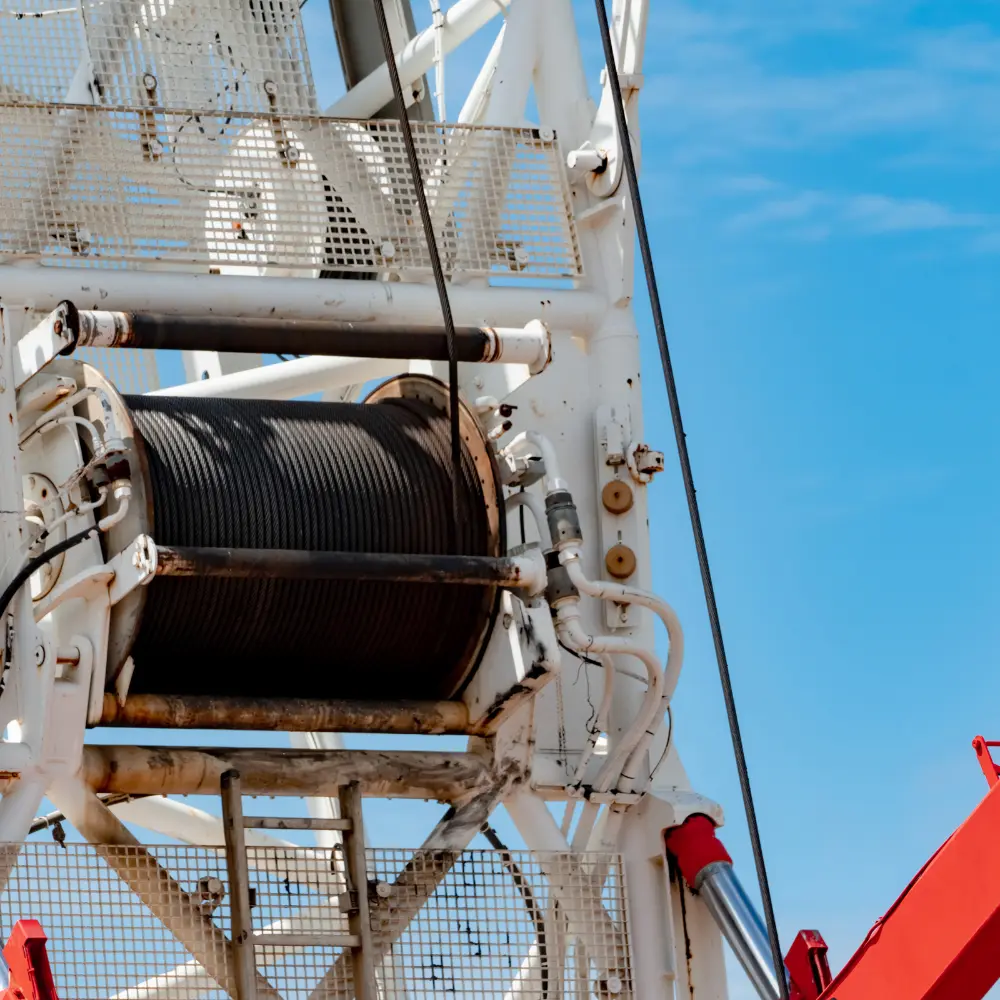

Steel wire ropes are widely used in construction, mining, and marine industries for their high strength and durability. However, they are susceptible to corrosion, especially under harsh environmental conditions.

Material Composition: Steel wire ropes are typically made from carbon steel or alloy steel. The inclusion of alloying elements like chromium and nickel enhances corrosion resistance. Stainless steel, which contains significant amounts of chromium, exhibits better resistance to rust and other forms of corrosion.

Protective Coatings: Applying protective coatings to steel wire ropes is a standard method to improve corrosion resistance. Galvanization, involving coating the steel with zinc, is widely used to protect against rust. Other coatings, such as plastic or polymer, provide barriers against moisture and chemicals.

Environmental Factors: Exposure to moisture, humidity, and chemicals can accelerate the corrosion process. For instance, steel wire ropes exposed to sulfuric acid show significant corrosion, highlighting the impact of chemical exposure on the longevity of the ropes.

Lubrication: Proper lubrication can help reduce corrosion by providing a protective layer between the steel surface and corrosive agents. Various lubricants can enhance corrosion resistance and protect the organic cores from biological attacks.

Synthetic Ropes

Synthetic ropes, made from nylon, polyester, and polypropylene, are increasingly used as alternatives to steel wire ropes, particularly in environments where corrosion is a significant concern.

Material Properties: Synthetic materials are inherently corrosion resistant as they do not undergo oxidation like metals. This makes them suitable for use in marine and chemical industries where exposure to corrosive elements is expected.

Environmental Resistance: Synthetic ropes are less affected by environmental conditions such as moisture and chemicals. However, they may degrade under prolonged exposure to UV radiation and extreme temperatures, affecting their mechanical properties over time.

Comparative Performance: While synthetic ropes offer excellent resistance to corrosion, they may sometimes provide a different strength and load-bearing capacity than steel wire ropes. This limitation necessitates careful consideration when selecting ropes for heavy-duty applications.

Getting the Right Wire Rope for the Job (Synthetic or Stainless Steel Wire Rope)

The effectiveness of different hoisting ropes at preventing corrosion is not solely dependent on their inherent properties, but also on the proactive measures taken by the industry professionals. Regular maintenance and appropriate selection of hoisting ropes, considering factors like material composition, protective coatings, environmental exposure, and maintenance practices, can significantly mitigate the risks of corrosion.

- Steel wire ropes, while solid and durable, require additional protective measures and regular maintenance to mitigate corrosion risks.

- Synthetic ropes offer superior corrosion resistance but may only sometimes match steel wire ropes' strength and load bearing capabilities.

Related Reading