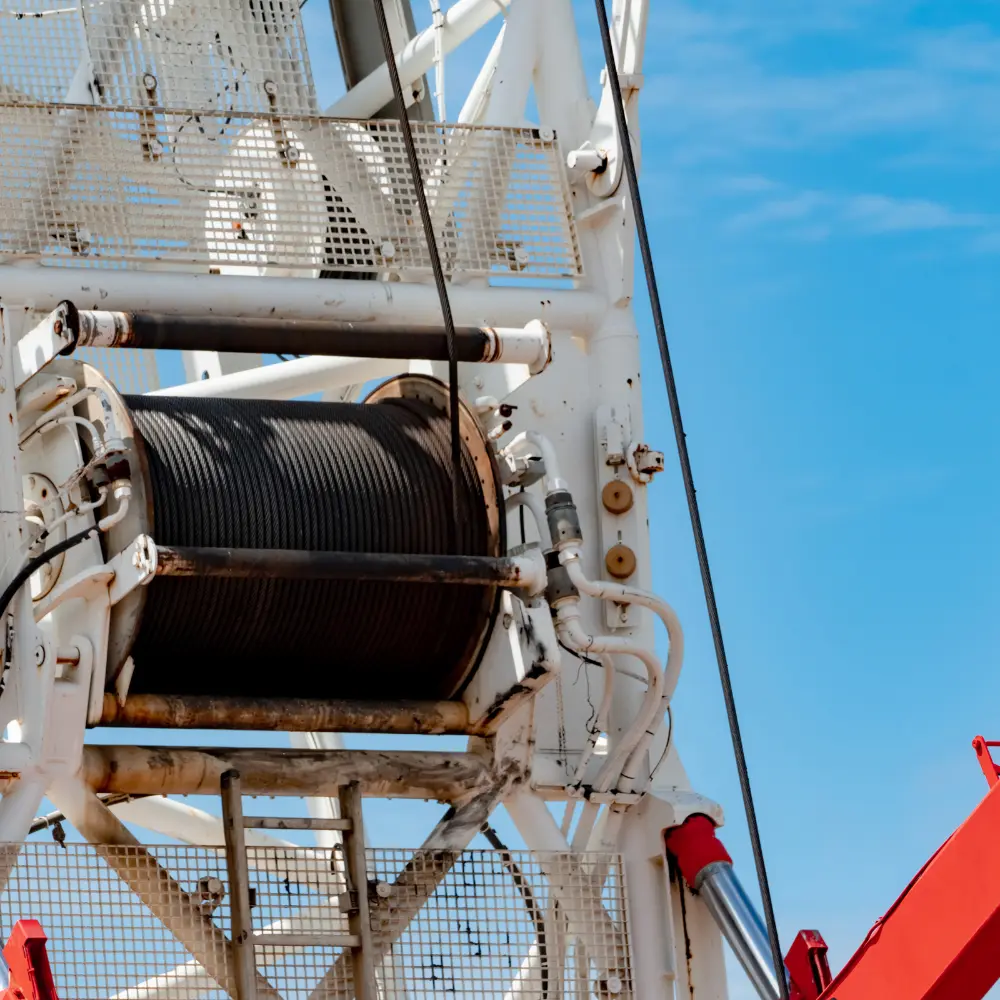

The structural integrity of sling wire ropes is crucial in various industrial applications, including materials handling, lifting processes, and anchoring systems. These ropes are designed to bear significant loads, and understanding the impact of axial forces on their structural integrity is essential for ensuring their safe and effective use.

The structural integrity of sling wire ropes is crucial in various industrial applications, including materials handling, lifting processes, and anchoring systems. These ropes are designed to bear significant loads, and understanding the impact of axial forces on their structural integrity is essential for ensuring their safe and effective use.

Understanding Axial Loading in Sling Wire Ropes

Axial loading is crucial to understanding the primary force that sling wire ropes encounter. This force involves forces applied along the rope's axis and significantly influences the rope's structural behavior, including how these forces are distributed across the strands and the resulting stresses and deformations.

For businesses utilizing or purchasing wire ropes, prioritizing ropes designed to manage axial forces effectively is critical. Ensuring the ropes can handle these forces enhances their performance and longevity, leading to safer and more reliable operations.

Insights from Finite Element Analysis (FEA)

Finite Element Analysis (FEA) plays a crucial role in simulating and studying the behavior of sling wire ropes under various loading conditions, offering insight into the interactions between individual wires within the rope and the overall response to axial forces. FEA provides a basis for selecting wire ropes with the best business structural properties. Understanding the results of FEA helps ensure that the ropes chosen can withstand the operational stresses they will encounter, leading to more informed and confident purchasing decisions.

Axial Force Distribution and Stress Behavior

An evenly distributed axial force across the wire rope ensures uniform stress distribution in practical applications. The linear contact model predicts consistent axial strain and von Mises stresses across the wire rope. However, incorporating nonlinear frictional contact into the model reveals an improved stress distribution due to friction between wires. This results in better load-bearing capacity and reduced deformation, particularly on the outer wires.

Businesses should prioritize wire ropes designed with frictional contact considerations, offering superior performance. Ensuring wire ropes are manufactured to optimize frictional interactions can significantly enhance their durability and safety.

Implications of Axial Strain Application

Applying axial strain incrementally to wire ropes highlights the importance of strain management in maintaining structural integrity. The results show that nonlinear models, which account for frictional effects, offer superior stress distribution compared to linear models.

This implies that wire ropes capable of managing axial strain effectively are better suited for high-stress applications, a crucial awareness for your operations. For businesses, selecting wire ropes tested and proven to handle axial strain efficiently can lead to improved performance and longevity.

*Ropes with these characteristics reduce the need for frequent replacements and minimize operational downtime, ensuring continuous and safe operations.

Trust the Pros

FEA effectively analyzes the structural integrity of sling wire ropes under axial loading conditions. Both linear bonded and nonlinear frictional contact models provide valuable insights into the stress distribution and deformation behavior. The results emphasize the significance of considering frictional effects and optimizing wire configuration to enhance the performance and safety of sling wire ropes.

Related Reading