Comparing the Differences Between Stainless Steel Wire Rope vs. Galvanized Steel Wire Rope: When to Choose Stainless Steel

In the dynamic world of material handling and safety gear, selecting the right component can significantly influence operational efficiency and safety. As providers and experts in this field, we often grapple with the choice between stainless steel and galvanized steel wire ropes for our clientele.

In the dynamic world of material handling and safety gear, selecting the right component can significantly influence operational efficiency and safety. As providers and experts in this field, we often grapple with the choice between stainless steel and galvanized steel wire ropes for our clientele.

- Fundamental Material Characteristics - Differences between the two.

- Stainless Steel Wire Rope: This wire rope has a minimum of 10.5% chromium content by weight. This composition imparts notable resistance to corrosive environments due to forming a passive oxide layer, which regenerates when scratched or cut.

- Galvanized Steel Wire Rope: Essentially consists of steel that has undergone a process of hot-dip galvanization, where the wire is coated with a protective layer of zinc, enhancing its corrosion resistance.

- Corrosion Resistance in Marine Environments - In marine applications with high saline content, stainless steel, particularly the 316 grade, offers superior resistance due to its inherent material properties. The added molybdenum in this grade offers enhanced protection against chloride-induced corrosion. In contrast, while galvanized steel does provide corrosion protection, it may fall short in highly saline environments, with the zinc layer potentially deteriorating over time.

- Thermal Resilience - Stainless steel wire ropes display commendable fire resistance, given their alloying constituents. In environments with anticipated elevated temperatures or potential fire hazards, stainless steel's thermal stability and reduced heat-induced degradation make it a clear frontrunner.

- Economic Considerations - While initial procurement costs for stainless steel wire ropes are generally higher than their galvanized counterparts, it is essential to factor in life cycle costs. The longevity and reduced maintenance requirement of stainless steel, especially in corrosive environments, can lead to long-term savings.

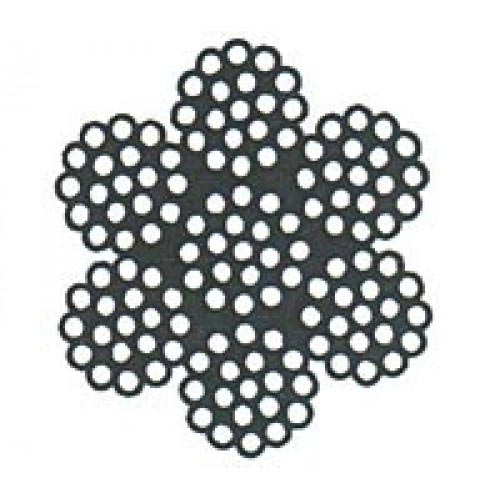

- Application-Specific Considerations - Engineers must evaluate the specific requirements of a project. For applications requiring high fatigue resistance, bending stiffness, or resistance to metal loss and deformation, specialized wire rope compositions and constructions must be considered.

The decision between stainless steel and galvanized steel wire rope should be grounded in a comprehensive understanding of the project requirements, environmental conditions, and long-term operational considerations. While galvanized steel may be suitable for specific applications, when corrosion resistance, thermal resilience, and longevity are paramount, stainless steel stands out as a superior engineering choice.

Related Reading