The first step in understanding the differences is defining what each term means. While steel cable and wire rope are similar, their construction standards and intended uses set them apart in critical ways. Misunderstanding these definitions can result in selecting the wrong material, leading to failures and increased costs.

The first step in understanding the differences is defining what each term means. While steel cable and wire rope are similar, their construction standards and intended uses set them apart in critical ways. Misunderstanding these definitions can result in selecting the wrong material, leading to failures and increased costs.

What is Wire Rope?

Wire rope is defined as a multi-strand structure of steel wires twisted around a core, with a diameter typically larger than 3/8 inches. Each strand is composed of individual wires that are helically twisted for increased strength and flexibility. The wire rope core may be made of steel (for strength) or fiber (for flexibility). This layered structure ensures the rope can handle enormous loads while maintaining durability in demanding conditions.

Wire rope classifications follow industry standards such as ASTM specifications, including common steel grades like AISI 302/304 or 316 stainless steel. These specifications determine corrosion resistance, tensile strength, and fatigue endurance—critical factors when selecting the right wire rope for a specific job.

What is Steel Cable?

Steel cable, often called "aircraft cable" in specific industries, is generally defined as a steel rope with a diameter smaller than 3/8 inches. Though similar in composition to wire rope, steel cables are constructed with fewer strands and wires, emphasizing flexibility over maximum strength.

Steel cable is frequently found in applications requiring lightweight but robust solutions. Configurations such as 1x7 or 7x19 (indicating one strand of seven wires or seven strands of nineteen wires) provide varying degrees of flexibility and tensile capacity, making the cable adaptable for tasks requiring precise movement or secure fastenings.

Structural and Mechanical Differences

Understanding the structural differences between steel cable and wire rope is essential for choosing the right option for your project. Their internal configurations, core materials, and twisting patterns directly impact their mechanical properties, from load capacity to durability.

Core Material and Construction

The core defines the cable's or rope's fundamental strength and flexibility. Wire ropes may feature:

- Fiber Cores (FC): Made from natural or synthetic fibers, providing flexibility but less strength.

- Independent Wire Rope Cores (IWRC): Constructed from steel strands, significantly boosting tensile capacity and heat resistance.

In contrast, steel cable typically lacks a complex core structure due to its smaller diameter, relying solely on its strands' configurations for performance.

Twist and Lay Patterns

How wires are twisted within a rope or cable determines flexibility, wear resistance, and longevity. Wire ropes are built with specific lay patterns, including:

- Regular Lay: Wires are twisted opposite the rope's overall twist, balancing flexibility and resistance to crushing.

- Lang Lay: Wires twist in the same direction as the rope, offering superior abrasion resistance but reduced stability.

Steel cable typically comes in fewer configurations due to its specialized applications, such as 7x7 or 7x19, optimizing flexibility and break strength.

Performance Comparison

When selecting between steel cable and wire rope, performance characteristics like load capacity, abrasion resistance, and fatigue endurance play a crucial role. Understanding how each performs under specific conditions can help prevent failures and extend service life.

Load Capacity: Strength Where It Counts

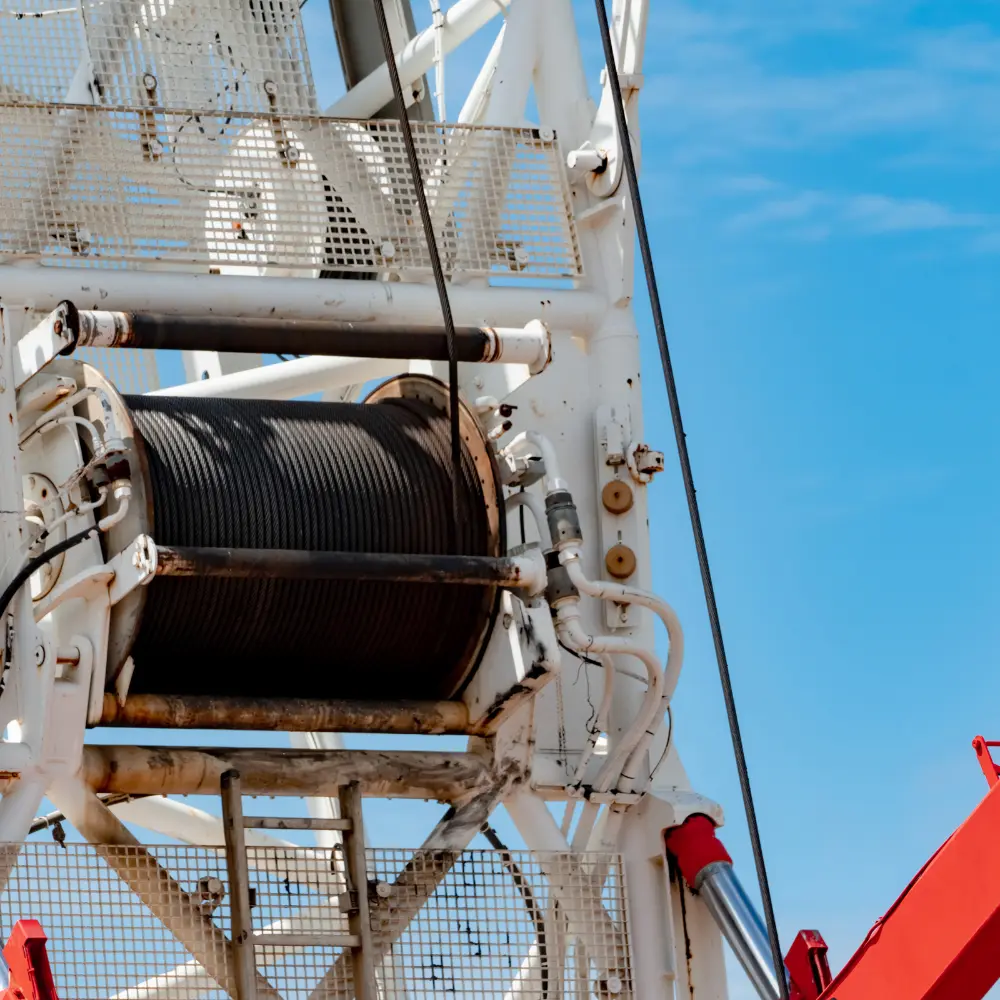

Wire rope is engineered for heavy-duty load-bearing applications due to its complex structure, which maximizes tensile strength. Industrial uses like cranes, winches, and construction hoists depend on wire rope for lifting immense loads without deformation.

Steel cable, though strong, is not built for such demanding tasks. Its primary strength lies in lightweight fastening, precise movement control, and secure anchoring. For example, aircraft cables stabilize control surfaces and secure cargo, making them indispensable in aviation and logistics.

Abrasion and Fatigue Resistance: Standing the Test of Time

Wire rope's multi-strand design offers superior abrasion resistance, reducing wear in harsh environments. However, its individual wires may break under repeated stress if not properly maintained. Protective coatings like galvanized steel, PVC, or nylon can enhance lifespan by resisting corrosion and surface damage.

Steel cable excels in flexibility and tight bending performance, allowing it to be used in precise operations like stage rigging, zipline systems, and pulley mechanisms. However, its thinner wires are more prone to wear, making regular inspections critical.

Common Applications and Use Cases

The practical applications of steel cable and wire rope highlight their differences. Each material excels in specific roles based on strength, flexibility, and environmental conditions.

Wire Rope Applications

- Construction: Used in cranes, elevators, and support structures where heavy loads are a constant factor.

- Heavy Industry: Essential in mining, logging, and shipyard operations that demand rugged, load-bearing capabilities.

- Structural Engineering: Provides critical support in suspension bridges, large-scale infrastructure, and high-rise buildings.

Steel Cable Applications

- Aircraft Control: Ensures precise movement of flight systems, keeping aviation operations safe and efficient.

- Marine Securing: Commonly used to secure cargo and vessels in harsh, saltwater environments.

- Adventure Systems: Found in ziplines, climbing setups, and emergency rescue operations where flexibility and strength are essential.

Making the Right Wire Rope Choices

While steel cable and wire rope may initially appear interchangeable, their construction, capacity, and application differences make them distinct tools in demanding industries. Selecting the correct option is critical to ensuring operational success and on-site safety.

Related Reading