If you've ever worked up close with cranes, hoists, or elevators, you'll know that the heart of these giants is often a seemingly simple component: the wire rope. Yet, like a medical check-up for our hearts, these ropes need regular testing. Let's delve into some real-world reasons why this is vital.

If you've ever worked up close with cranes, hoists, or elevators, you'll know that the heart of these giants is often a seemingly simple component: the wire rope. Yet, like a medical check-up for our hearts, these ropes need regular testing. Let's delve into some real-world reasons why this is vital.

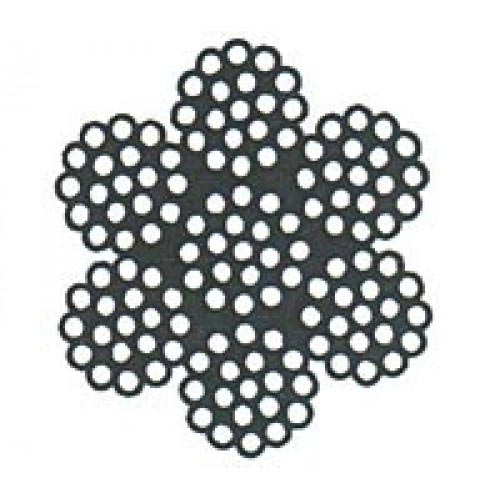

Wire Rope

- Lifespan Matters: Think of it this way - if you service your car regularly, it's likely to run smoother and longer. Similarly, some industry insiders believe that tested and well-maintained wire ropes can outlast their neglected counterparts significantly; some even suggest up to a quarter longer!

- Safety First and Always: Anyone familiar with OSHA's reports knows that many crane-related mishaps happen due to overlooked wire ropes. It's unsettling to think that a significant portion of these could be prevented with regular testing.

- Your Pocket Feels It, Too: Consider the scenario where a significant construction project grinds to a halt because a wire rope snapped. The unexpected downtime and repair costs can skyrocket, with some industry estimates suggesting figures in the thousands per hour!

- Performance Isn't Just About Power: Imagine pushing your car's engine past its limit daily; it's bound to wear out sooner. Wire ropes aren't any different. Pushing them beyond their limits without regular checks can severely hamper their efficiency.

- Staying Within the Law: There are enough challenges in industries reliant on heavy lifting; legal troubles shouldn't be one. Various regions have clear guidelines and standards. Regular testing ensures you're on the right side of the law.

- Avoiding Unexpected Breaks: It's a universally acknowledged truth in the industry: the wire ropes that are regularly checked and tested show slower degradation. It's like knowing when your running shoes are about to give out – it helps to be prepared rather than be caught off-guard.

To sum up, while technology and machinery evolve, some foundational practices remain unchanged. Testing wire ropes is one such practice – ensuring not just the longevity of the rope but the safety of all those reliant on it.

Related Reading