Wire rope is a top choice for many industries because they are reliable, durable, and built to last. While a crane wire rope is heavy-duty and high quality, they aren't immune to damage. With time, they can become damaged, especially if not properly maintained. One of the most common injuries to wire rope is bending. It's important that your rigging supplies, including wire ropes and nylon slings, are working efficiently to provide the safest working environment.

Wire rope is a top choice for many industries because they are reliable, durable, and built to last. While a crane wire rope is heavy-duty and high quality, they aren't immune to damage. With time, they can become damaged, especially if not properly maintained. One of the most common injuries to wire rope is bending. It's important that your rigging supplies, including wire ropes and nylon slings, are working efficiently to provide the safest working environment.

Bending commonly occurs around drums and sheaves. When performing daily inspections, ensure you thoroughly examine these areas for signs of bending. Bending of wire ropes can have many adverse effects, but the two most common are fatigue and loss of strength.

Fatigue

Signs of fatigue show themselves in the form of small cracks in the wire. The small cracks occur from repeated stress cycles. Repeated stress cycles will cause the remaining sound metal to be unable to withstand the bending load.

Loss of Strength

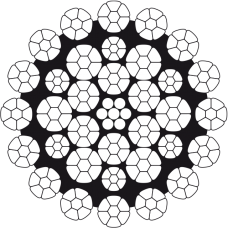

When wire rope bends, it readjusts the positions of the wires and strands. This results in bending. As the rope becomes bent, the individual wires and strands cannot adjust to their changed position. When this happens, the wire rope cannot perform to its maximum capacity. This effect is especially dangerous because you may inadvertently overload your wire rope.

Related Reading about Wire Rope