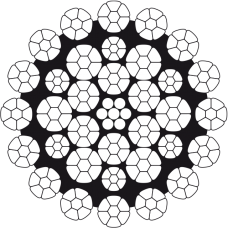

Wire ropes are constructed from several strands of metal wires that get twisted into a helix. This process forms a composite rope, which is also referred to as a laid rope. As the ropes' diameter grows, laid ropes are used (cabling). Wire ropes are considered complex mechanical devices constructed from multiple moving parts that all work together to support and move loads or objects.

Wire ropes are constructed from several strands of metal wires that get twisted into a helix. This process forms a composite rope, which is also referred to as a laid rope. As the ropes' diameter grows, laid ropes are used (cabling). Wire ropes are considered complex mechanical devices constructed from multiple moving parts that all work together to support and move loads or objects.

In the rigging and lifting industries, wire ropes are attached to hoists and cranes and are fitted with other accessories, like shackles, swivels, and hooks. These ropes are also commonly used in elevators and suspension bridges/towers. Wire rope is often seen as the most preferred lifting tool. Considering how complex and important these ropes are, below, we want to go over terms that can help individuals define the properties and construction of a given rope.

1) Strand Patterns – Looking at the end of a rope, you can see the number of layers within the rope. The number of wires per lay plus the size of the wire per layer directly affect strand pattern types.

2) Direction/Type of Lay – how wires are laid to form strands helps determine a wire rope's characteristics. The three most common lays include:

· Lang Lay – greater fatigue resistance and resistance to abrasion

· Alternate Lay- used in special applications

· Regular Lay – resistant to crunching forces and rotation resistant

3) Wire Rope Finish – wires are coated to enhance and add characteristics to final products. There are several material coatings options, such as galvanized zinc, aluminum alloy, and stainless steel. In short, wire finishing is broken down into three categories, which include:

· Bright – used in general applications

· Galvanized – great corrosion resistance

· Stainless Steel – able to resist corrosion. Great in marine environments and applications.

Many other aspects of wire rope help to define properties and constructions, but the three above are the most important. For more information, you can refer to the user manual provided by the manufacturer.

Related Reading about Wire Rope