Before using new wire ropes, they must be inspected to ensure they are safe to use. Many things can occur during shipping, so it is better to be safe than sorry. Besides inspecting ropes for damage, it is also vital to measure wire ropes to ensure they work with your crane. Many wire ropes measure slightly more than their nominal diameter.

As wire ropes age and wear down, they measure less than initially. They will also measure less than the new ropes being installed. As a result, you will want to keep records of the new diameter to have it for future reference. It may be essential to know how much the ropes' diameter has decreased over any specific amount of time. Knowing this allows users to make intelligent changes.

Wire Rope

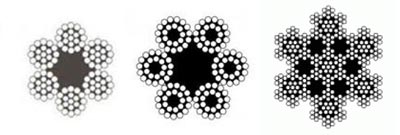

When measuring the diameter of a wire rope, it is essential to remember that the actual diameter is that of the circumscribed circle that includes all the strands. The diameter must be measured at the largest crossed sections. To make the job easier, you need the right tools, which in this case includes calipers. Use digital calipers over traditional versions because the digital variant offers higher proficiency and more accessible readouts. It is easy to make inaccurate measurements by starting measurements at the wrong point.

It is possible to measure without a caliper, using a piece of string, a ruler, and a calculator, but these calculations only give a reasonable estimate.

Related Reading about Wire Rope