Crane wire rope is an essential component of many businesses. They are used in multiple applications and industries. Wire rope is vital to lifting, moving, and unloading goods. Proper routine inspections must be performed to ensure the safety of all those around the workplace. All those who will operate the machinery should know how to perform a daily inspection before use. Daily inspections ensure the safety of workers and can spot any tears, bends, or other damage before it worsens.

Crane wire rope is an essential component of many businesses. They are used in multiple applications and industries. Wire rope is vital to lifting, moving, and unloading goods. Proper routine inspections must be performed to ensure the safety of all those around the workplace. All those who will operate the machinery should know how to perform a daily inspection before use. Daily inspections ensure the safety of workers and can spot any tears, bends, or other damage before it worsens.

Inspections on crane wire rope will be done in two ways: visual and internal inspection. A visual inspection is performed daily. An internal one is performed one to four times a month, depending on the age of your crane. Let's go over tips for each one.

Visual Inspection

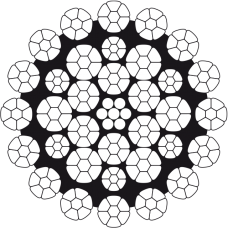

Visual inspections must be performed before and after each working shift. These daily inspections are essential in ensuring there's no damage to the wire rope. Inspect all areas of the wire rope, including the shaft, reel, sheave, and hook connected to the end of the wire rope. To ensure proper maintenance, ensure the following processes are included in the inspection: friction generation, lubrication, and damage control.

Internal Inspection

Perform an internal inspection once a week on older cranes and twice a month for newer machinery. During this process, the operator will do a complete assessment of the wire rope, including checking the material, distance between the clamping jaws, and height and weight optimization.

Related Reading about Crane Wire Rope