Selecting the right wire rope for your crane isn't just about making a purchase; it's about making a wise, informed decision that affects the safety, efficiency, and operational longevity of your lifting tasks. This guide delves into the critical factors you need to consider, supported by specific examples and essential considerations, to ensure you select the best wire rope.

Selecting the right wire rope for your crane isn't just about making a purchase; it's about making a wise, informed decision that affects the safety, efficiency, and operational longevity of your lifting tasks. This guide delves into the critical factors you need to consider, supported by specific examples and essential considerations, to ensure you select the best wire rope.

- Understanding Load Requirements: Assessing Maximum Load and Lift Frequency - Before anything else, knowing what your wire rope will be lifting is crucial. Imagine lifting heavy steel beams on a construction site; your wire rope's breaking strength must surpass the heaviest beam's weight. Remember, a rope's "Breaking Strength" diminishes with wear and metal fatigue. Thus, understanding both the maximum load and the frequency of lifts is foundational.

- Maximum Load: Determine the heaviest weight the wire rope needs to support.

- Lift Frequency: Opt for a wire rope with high fatigue resistance for frequent lifting.

- Selecting the Right Core and Construction: Core Types and Construction Varieties - The wire rope's core and construction significantly impact its performance.

- Core Types: IWRC (Independent Wire Rope Core) is preferred for heavy-duty lifting due to its strength and resistance to crushing and heat. For lighter applications, a fiber core might be more appropriate for its flexibility.

- Construction Type: The construction, such as a 6 x 19 configuration, balances flexibility and abrasion resistance. This specification is critical to determining the rope's suitability for your operations.

- Considering Environmental Conditions: Corrosion, Chemical Exposure, and Temperature - The working environment affects your wire rope choice. Selecting a corrosion-resistant wire rope is vital for corrosion or chemical exposure areas. The operating temperature range can also dictate the core material, with IWRC cores preferable for high-temperature applications.

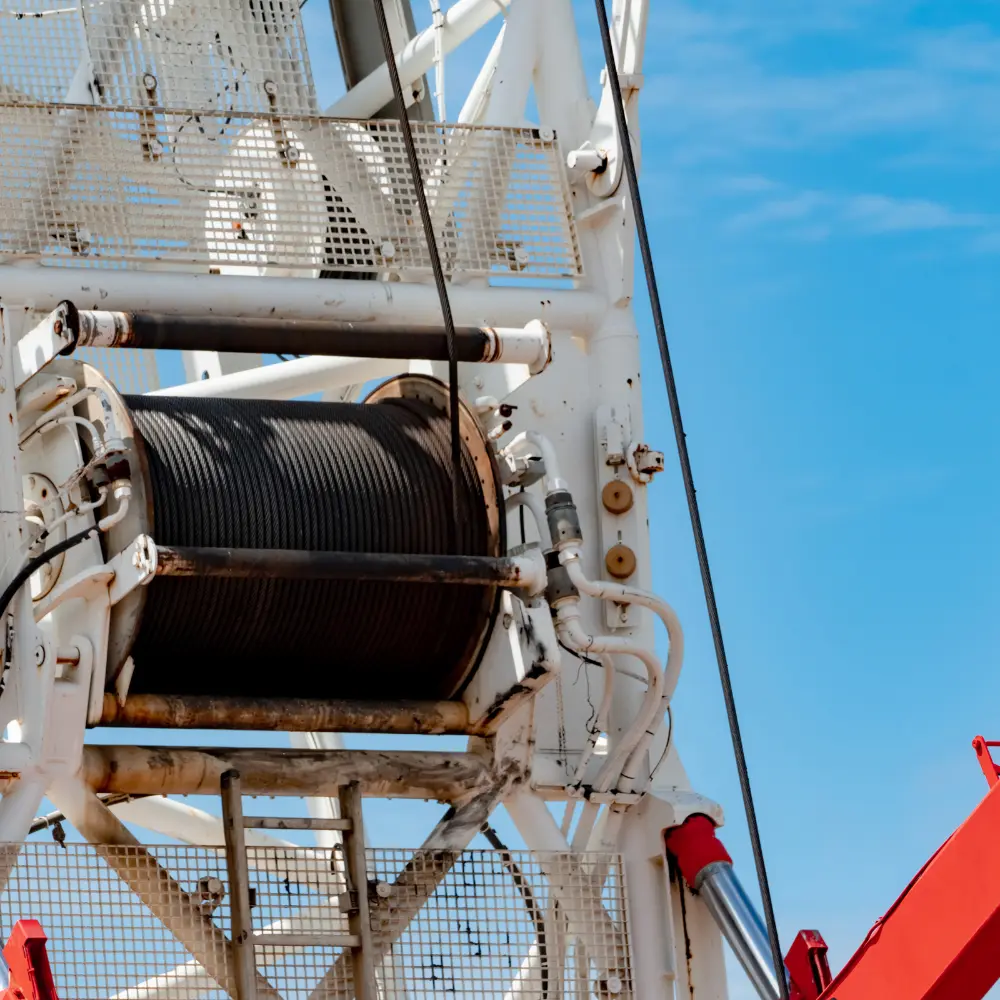

- Determining Diameter and Length: Practical Measurement Considerations - Accurate measurements ensure the wire rope fits your crane's sheave and drum perfectly and is long enough for your lifting needs. An ill-fitting wire rope can lead to kinking, excessive wear, and failure.

- Compliance and Quality Standards: Ensuring Safety and Efficiency - Adherence to quality standards (e.g., ASTM, ISO) is non-negotiable. Selecting wire ropes from reputable manufacturers who offer warranties can further assure you of the product's reliability and longevity.

- Quality Standards: Look for ropes that meet or exceed industry standards for safety and performance.

- Manufacturer's Reputation: Choose products from manufacturers known for their quality and reliability.

This guide underscores the importance of a detailed, informed approach to selecting wire rope for crane operations. These factors help you make a choice that enhances operational safety and efficiency, backed by the confidence of compliance with industry standards.

Related Reading