Wire ropes are common devices that are used all around us. From construction and infrastructure to material handling, these ropes service many common and important applications. Considering the wide range of applications of wire ropes, there are many different wire rope options to choose from. Many construction factors determine the performance characteristics of ropes. How do you make sure you pick the right wire rope for a specific application?

There are several questions to consider and answer, which will help you to narrow your options. You can always reach out for help making a final choice. What are the most important questions to ask?

What application do the ropes need to complete? Wire ropes for architecture and lifting might be similar, but they differ from ropes used for marine and fishing applications. How will you use the rope, and what environment does it operate in? If your ropes remain outdoors, you need to ensure they have high levels of corrosion resistance.

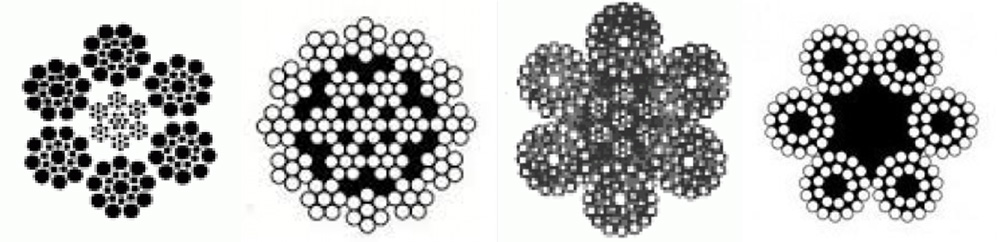

What is your product range? A galvanized wire rope comes in many cores size options, including 6x7, 6x24, 6x36, 7x7, 7x19, and more. Stainless steel wire ropes come in several grades, which include 304 and 314. If you are shopping for coated wires, you can find PVC-coated 7x7 and 7x19 wire rope constructions.

What features do you require for consistent and optimal performance? Non coated bright ropes are considered a general-purpose, standard grade, whereas Type 304 & 316 Stainless Steel is for marine applications. Harsh environments (marine, water, chemical) are better suited when using 316 marine-grade ropes. PVC-coated wire ropes are softer to the touch, flexible, and highly resistant to harsh UV rays.

Related Reading