Understanding Four Key Components of Wire Ropes

Wire rope is known as a complex piece of mechanical machinery that is created in a few different properties and specifications that directly influence its performance and service life. Knowing the difference between specifications and construction allows for easier access to optimal wire ropes.

Using improper ropes causes damages to the machine, to people, and to products. Each job requires a specific type of wire rope or vrope.

Knowing the four components of wire ropes helps individuals to navigate to specification and construction types that best meet lifting demands. Each job is different, and so it is essential to acquire ropes that can safely accomplish the tasks at hand.

Outside material: the metal that sits on top of the core helps to determine strength, flexibility, and lubrication needs.

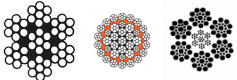

The lay of the multi-wire strands (around the core): wire ropes are constructed in different ways, and each different way has its pros and cons. The way wires are wrapped around the core matter for rope performance.

Core material: a core is usually constructed from either fiber or steel.

Lubrication: wire ropes need to remain lubricated, but depending on the metals, core, and lay used to construct the, you may need more or less lubrication.

Be mindful when shopping, and make sure to research all aspects of the wire rope. For more information about finding the perfect match for your business, you should not hesitate to give our knowledgeable staff a call.

Related Reading about Vrope