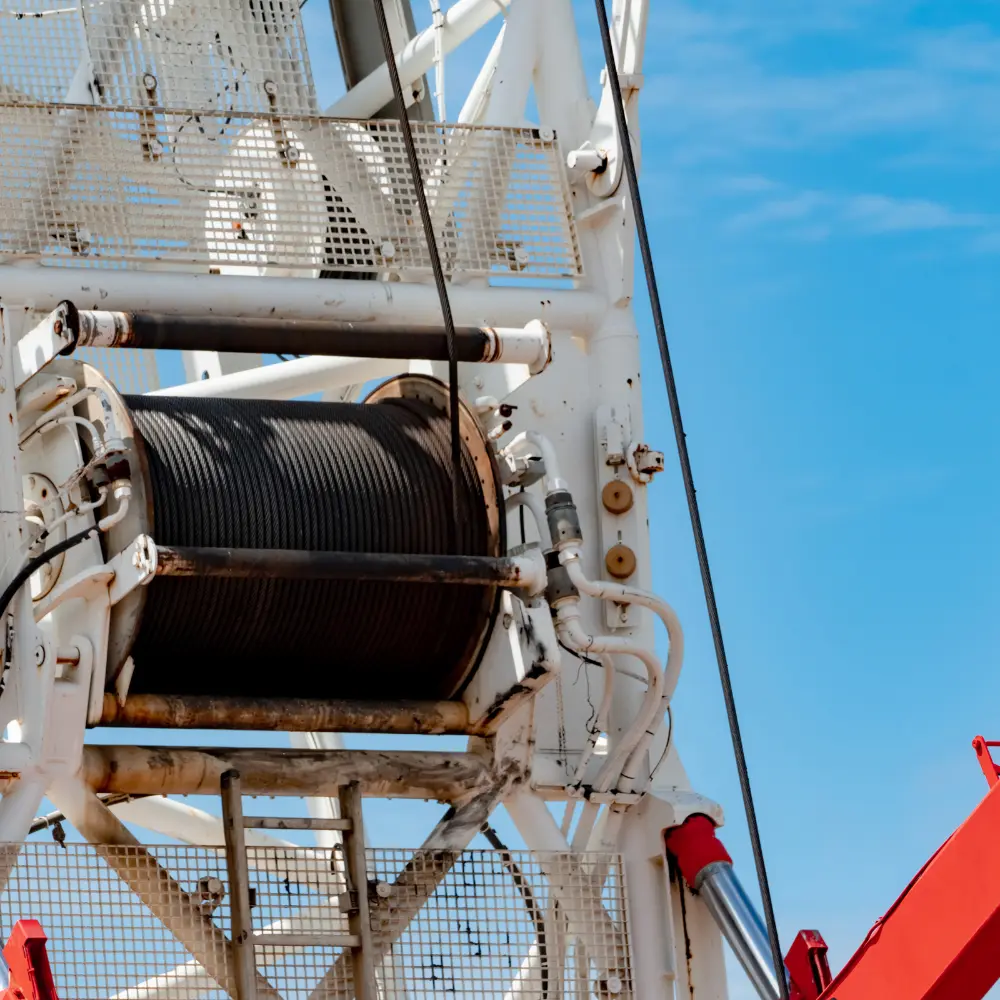

The wire rope you choose for your crane is not just a component, it's a crucial factor in ensuring the safety and efficiency of your operations. Whether you're dealing with the daily grind of heavy lifting, the need for high rotation resistance, or the harsh conditions of high-temperature environments, the wire rope you select can have a profound impact on your project outcomes.

The wire rope you choose for your crane is not just a component, it's a crucial factor in ensuring the safety and efficiency of your operations. Whether you're dealing with the daily grind of heavy lifting, the need for high rotation resistance, or the harsh conditions of high-temperature environments, the wire rope you select can have a profound impact on your project outcomes.

Many businesses find themselves in a tough spot, trying to find a wire rope that meets their needs-from breaking strength to flexibility and environmental suitability. Verope offers a range of specialized wire ropes designed to tackle these challenges head-on, providing reliable solutions tailored to various applications and operational requirements.

Verotop P

Verotop P is a meticulously engineered rotation-resistant wire rope. Its compacted strands and core, covered with a precise plastic layer, ensure high breaking strength and excellent spooling behavior on multilayer drums. With a nominal rope diameter range from 16 mm (5/8 inch) to 54 mm (2-1/8 inch), and an approximate mass varying from 1.248 kg/m to 14.211 kg/m, this rope is designed to meet your specific needs. The minimum breaking force ranges between 24.6 tons (1960 grade) and 283.6 tons (2160 grade), providing a stable rope structure, excellent bending fatigue results, and perfect spooling behavior. It can be used with or without a swivel and is a category one rotation-resistant rope by ASTM A1023.

Main Benefits:

High breaking strength

Excellent spooling behavior

Stable rope structure

Best Applications and Environments:

Multilayer drum spooling

Heavy lifting operations

Construction and industrial cranes

Verotop XP

Verotop XP is a rotary-swaged, rotation-resistant rope with compacted strands and a plastic-covered core. It is suitable for environments requiring superior crushing resistance and abrasion resistance. Verotop XP's nominal rope diameter spans from 12 mm (0.720 kg/m) to 48 mm (11.526 kg/m), with the minimum breaking force ranging from 14.3 kN (1960 grade) to 228.9 kN (2160 grade). This rope has a stable structure, good bending fatigue results, and excellent spooling behavior on multilayer drums. It can be used with or without a swivel and meets category one rotation-resistant standards by ASTM A1023.

Main Benefits:

Superior crushing resistance

Excellent abrasion resistance

Good bending fatigue results

Best Applications and Environments:

Harsh industrial environments

Heavy-duty cranes

Operations requiring rotation resistance

Veropro 8 and Veropro 10

Veropro 8 is a non-rotation-resistant rope with compacted outer strands and a plastic-covered core. It is designed for general construction and heavy industry applications. Veropro 8's diameter ranges from 16 mm (5/8 inch) to 54 mm (2-1/8 inch), with a minimum breaking force of 24.6 tons (1960 grade) to 283.6 tons (2160 grade). Similarly, Veropro 10 is a very flexible, non-rotation-resistant rope with compacted strands and a plastic-covered core, ideal for scenarios requiring maximum flexibility. Its diameter ranges from 16 mm (1.281 kg/m) to 48 mm (11.526 kg/m), with breaking forces between 24.6 tons (1960 grade) and 231.7 tons (2160 grade).

Main Benefits:

High flexibility

Strong and durable

Suitable for various applications

Best Applications and Environments:

General construction

Heavy industry

Applications needing flexible ropes

Verostar 8

Verostar 8 is a non-rotation-resistant rope with conventional strands and a plastic-covered core. It is optimal for port applications and general lifting tasks. Verostar 8's diameter ranges from 12 mm (0.720 kg/m) to 48 mm (11.228 kg/m), with a minimum breaking force ranging from 14.3 tons (1960 grade) to 221.6 tons (2160 grade). This rope suits various lifting applications, providing reliable performance across different environments.

Main Benefits:

Reliable performance

Versatile for different lifting tasks

Conventional strand design

Best Applications and Environments:

Port operations

General lifting tasks

Versatile industrial use

Verosteel 8

Verosteel 8 is a non-rotation-resistant rope with compacted outer strands, specifically designed for safety in steel mill environments and other high-temperature settings. Its diameter ranges from 12 mm (0.720 kg/m) to 48 mm (11.228 kg/m), with breaking forces from 14.3 tons (1960 grade) to 231.7 tons (2160 grade). This rope offers exceptional performance in high-temperature conditions, ensuring safety and reliability in demanding environments.

Main Benefits:

High-temperature resistance

Durable in harsh conditions

Compacted outer strands

Best Applications and Environments:

Steel mills

High-temperature environments

Heavy industrial use

Ensuring Optimal Wire Rope Performance

Choosing the suitable Verope wire rope can significantly affect your operations' safety and efficiency. Whether you need high rotation resistance, flexibility, or durability in harsh environments, Verope has a solution tailored to your needs. Select the appropriate wire rope for your application to enhance performance and reduce downtime. For more information and expert advice, visit Verope's detailed product catalog and contact their team to find the perfect fit for your requirements.

Related Reading