Following guidelines or a checklist is one of the smartest things to do to remain safe on the job: this rule sticks regardless of the industry. For businesses that engage in more intense, dangerous work, the rule applies even more because lives are on the line.

Following guidelines or a checklist is one of the smartest things to do to remain safe on the job: this rule sticks regardless of the industry. For businesses that engage in more intense, dangerous work, the rule applies even more because lives are on the line.

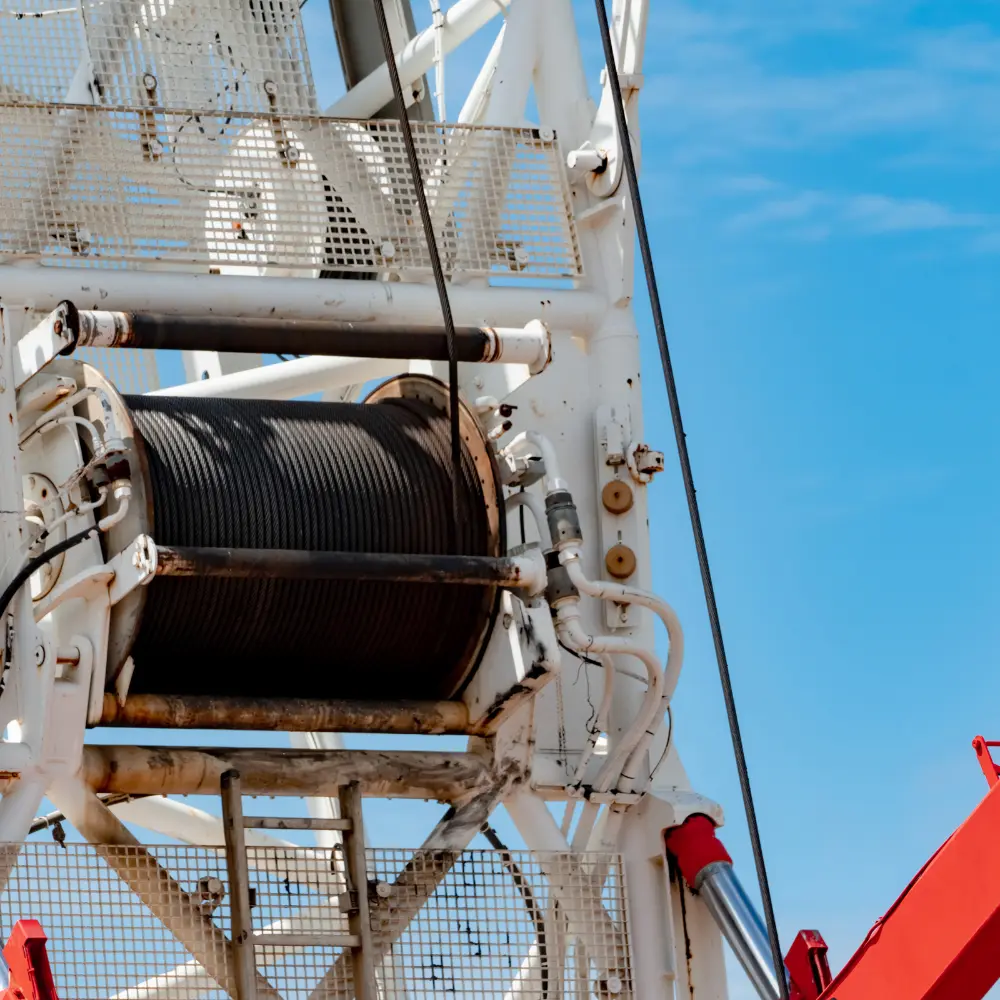

Those that use wire rope and rigging supplies know firsthand how small mistakes can cause serious consequences. It is essential to recognize that a wire rope can only work as well as it was installed, meaning that improper installation can lead to tragedy. Below we give an overview of the most important aspects of installing wire rope. It is important to first understand manufacturer guidelines for each individual wire rope and lifting supplies you use.

Checklist for Wire Rope Installation

- Selection of Wire Rope: Ensure you choose the right wire rope for your specific application. Consider factors like rope diameter, construction type, core type, tensile strength, flexibility, and environmental conditions.

- Handling and Storage: Before installation, handle the wire rope with care to avoid kinking or twisting. Store it properly, away from moisture and chemicals that can cause corrosion.

- Inspection: Inspect the wire rope for any damage or wear. Look for broken wires, severe wear, kinks, rust, and any deformations.

- Proper Tools and Equipment: Use the correct tools for cutting, splicing, and terminating the wire rope. This includes wire rope cutters, swagers, and thimbles.

- Cutting the Rope: If you need to cut the wire rope, do it cleanly and squarely. Use sharp, appropriate cutting tools to prevent fraying.

- Correct Threading: When threading the rope through pulleys or onto winches, ensure it is done smoothly without twists or kinks.

- Tensioning: Apply tension to the wire rope as per the requirement of the application. Over-tensioning can lead to premature failure, while under-tensioning might result in slippage or uncontrolled movement.

- Avoid Sharp Bends: When installing, avoid running the wire rope over sharp corners or bends, as this can weaken the rope.

- Lubrication: Some wire ropes require lubrication for better performance and longevity. Use a suitable lubricant as recommended by the manufacturer.

- Regular Maintenance and Inspection: Once installed, regularly inspect the wire rope for signs of wear, corrosion, or damage. Replace it if necessary.

- Follow Safety Protocols: Always adhere to safety protocols. Wear appropriate personal protective equipment and ensure that the area is secure and safe for installation.

Remember, these are general guidelines. It's crucial to follow any specific instructions provided by the wire rope manufacturer or your workplace safety guidelines. If you're unsure or if the installation involves critical load-bearing applications, consulting with a professional is highly recommended.

Related Reading