In industries where wire ropes play a crucial role, repeated bending is an inevitable part of daily operations. Whether it's the constant lifting and lowering in construction cranes, the continuous motion in elevators, or the dynamic loads in suspension bridges, the integrity of these ropes is constantly challenged. Many have faced the frustration and safety risks of unexpected rope failures, costly downtimes, and the scramble for replacements. These common issues stem from the underlying degradation mechanisms that affect wire ropes when they are repeatedly bent. Understanding these problems is essential for improving safety, reducing maintenance costs, and ensuring reliable operations.

In industries where wire ropes play a crucial role, repeated bending is an inevitable part of daily operations. Whether it's the constant lifting and lowering in construction cranes, the continuous motion in elevators, or the dynamic loads in suspension bridges, the integrity of these ropes is constantly challenged. Many have faced the frustration and safety risks of unexpected rope failures, costly downtimes, and the scramble for replacements. These common issues stem from the underlying degradation mechanisms that affect wire ropes when they are repeatedly bent. Understanding these problems is essential for improving safety, reducing maintenance costs, and ensuring reliable operations.

Degradation Mechanisms Due to Repeated Bending

Fatigue in Wire Ropes

Repeated bending subjects wire ropes to cyclic stress, which is a principal factor leading to fatigue. Fatigue manifests in the form of microscopic cracks that propagate with each bending cycle. These cracks are primarily located at points of high-stress concentration, such as at the contact points between wires or the bend points over sheaves and drums.

Fatigue in wire ropes is a critical concern due to the cyclical nature of the loads they endure. Each time a wire rope bends, whether over a sheave, drum, or another structural component, it undergoes a stress cycle. The high-tension areas experience compression and elongation, leading to microscopic cracks over time. These cracks start small but can grow significantly with repeated loading and unloading cycles.

- Stress Concentration

- Localized Cracks: Consider a crane lifting heavy loads. Each lift subjects the rope to bending stresses as it passes over the sheave. Micro-cracks form at these high-stress points, particularly where the rope contacts the sheave.

- Propagation: As the crane continues its operations, the cracks propagate further with each cycle. This gradual deterioration is not immediately visible but significantly weakens the rope's structural integrity.

- Accumulation of Micro-Damage

- Initial Stage: The rope may show no outward signs of damage, even though micro-damages accumulate internally.

- Critical Stage: Over time, the accumulation reaches a critical threshold, leading to sudden and often catastrophic failure. For instance, a wire rope failure in mining operations can halt operations and pose serious safety risks.

Fretting Fatigue

Fretting fatigue arises from the frictional interaction between individual wires within the rope. This friction, exacerbated by repeated bending, leads to wear and localized fatigue failures. Fretting fatigue is especially problematic in applications where wire ropes are in continuous contact with other surfaces or themselves, such as in elevators or suspension bridges. Fretting fatigue is exacerbated by the minute, often repetitive movements that occur between wires. These movements cause frictional wear, leading to the degradation of the rope's surface and internal structure.

- Interwire Friction

- Heat Generation: In an elevator system, the rope constantly moves over pulleys. The friction between wires generates heat, reducing the lubricant's viscosity and leading to increased wear. The elevator's daily cycles cause constant fretting, accelerating rope degradation.

- Accelerated Wear: Reduced lubrication means that wires rub more directly against each other, which wears down the material faster and leads to premature failure.

- Fretting Zones

- Localized Fatigue: Specific zones where wires rub against each other experience higher stress concentrations, leading to accelerated fatigue. For example, the contact points within a wire rope used in a suspension bridge will develop fretting zones, particularly under high traffic loads, leading to potential failure points.

Wear

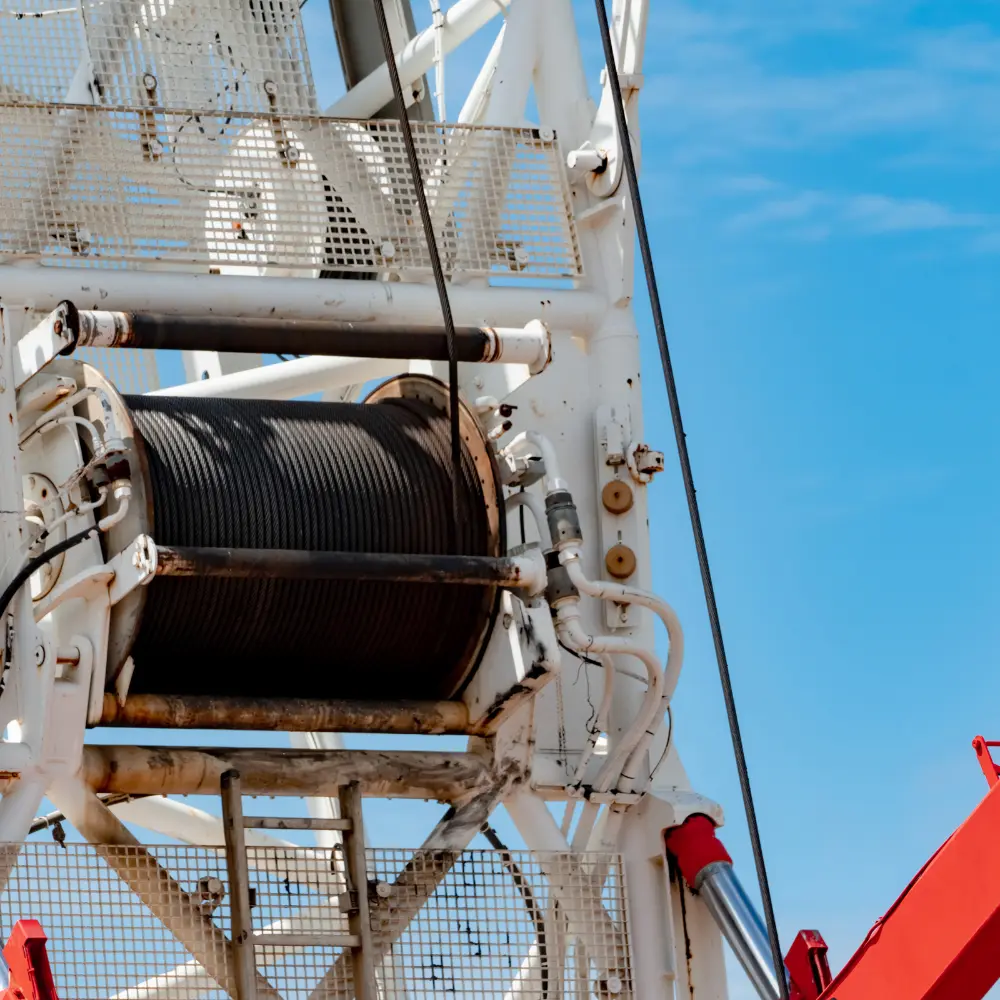

Wear in wire ropes due to repeated bending is a dual phenomenon encompassing internal and external wear. Internal wear occurs due to interwire contact, while external wear results from the rope bending over sheaves or drums. This wear process is gradual but relentless, significantly reducing the rope's operational lifespan.

- Internal Wear

- Interwire Abrasion: In a marine environment, wire ropes used for mooring undergo constant motion due to waves. The internal wires rub against each other, leading to gradual wear. This wear reduces the effective cross-sectional area of the wires, diminishing the rope's load-bearing capacity.

-

- Load Redistribution: As wires wear down, the load is unevenly redistributed among the remaining wires, increasing the stress on those wires. In a winch system, this can lead to sudden and unexpected failures.

- External Wear

- Sheave Contact: Consider a construction crane where the wire rope continuously runs over sheaves. The constant bending over the sheave causes external wear, which is visible as flattening or polishing of the rope surface. This wear not only reduces the rope's diameter but also affects its flexibility and strength.

- Groove Wear: If the sheaves are worn or have irregular grooves, they exacerbate the rope wear. This is often seen in older industrial equipment where maintenance of the sheaves has been neglected, leading to premature rope failure.

Corrosion

Corrosion is often accelerated by the repeated bending of ropes, especially when they operate in moist or corrosive environments. The bending action can break protective coatings and allow corrosive agents to penetrate. This is particularly concerning in offshore or maritime applications where saltwater exposure is common.

- Coating Damage

- Protective Layers: Wire ropes are frequently exposed to saltwater on offshore oil rigs. Repeated bending during lifting operations can crack the protective zinc coating, exposing the underlying steel to corrosive elements. This leads to pitting and surface rust, compromising the rope's strength.

- Moisture Penetration: Damaged coatings allow moisture to penetrate, leading to corrosion. For example, moisture ingress in a bridge's suspension cables due to damaged coatings can cause internal corrosion, significantly weakening the structure over time.

- Accelerated Corrosion

- Surface Area Increase: Cracks and wear increase the surface area exposed to corrosive agents. In industrial applications, where ropes are subjected to mechanical stress and chemical exposure, wear and corrosion can rapidly degrade the rope's performance.

- Strength Reduction: Corrosion reduces the cross-sectional area of the wires, diminishing their load-carrying capacity. This is critical in applications like mining, where rope integrity is paramount for safety.

Understanding the impact of repeated bending on wire rope integrity and performance is critical for ensuring their safe and efficient use in various industrial applications. By focusing on the specific degradation mechanisms—fatigue, fretting fatigue, wear, and corrosion—we can better predict and mitigate the effects of repeated bending, thereby enhancing the reliability and safety of wire rope systems. Regular maintenance, inspection, and the application of protective measures are vital in prolonging the operational life of wire ropes.

Related Reading